- About

- About Overview

- Vision & Values

- Leadership Teams

- Corporate

- Canadian Operations

- United States Operations

- Service Line

- Safety

- Quality

- Environment

- Sustainability

- Indigenous Policy

- Hellier Training

- Applied Inspection

- Engineering

- Engineering Overview

- Field Engineering

- Field Engineering Overview

- Ferrite Testing

- Hardness Testing

- Metallurgical Replicas

- Optical Emission Spectroscopy (OES)

- Positive Material Identification (PMI)

- Materials Testing & Analysis

- Materials Engineering

- Metallurgical Condition Assessment

- Steam Cycle Chemistry Services

- STRAP – Steam Turbine Risk Assessment Program

- Support for Industrial Insurers and Independent Adjusters

- Water Treatment Technologies Services

- Reliability Engineering

- Vibration Analysis

- Inspection

- Inspection Overview

- Advanced NDE/NDT

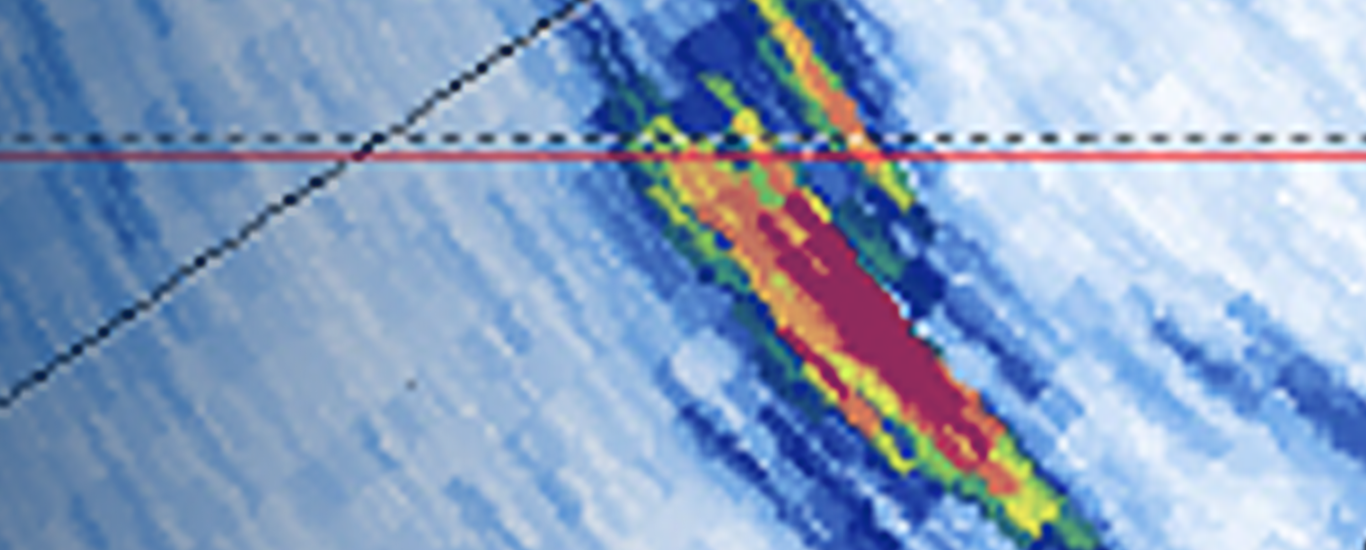

- Moisture Detection Imaging (MDI)

- Non-Intrusive/On Stream Inspection Program

- Phased Array Services

- Time of Flight Diffraction Technique (ToFD)

- Tube to Tube Sheet Weld Inspection

- NDE/NDT

- Visual Inspection (VT)

- National Board Program

- Drone & Robotic Inspection Services

- Lab Services – Inspection & NDT

- Rope Access for Inspection

- Inspection Training

- Rope Access Industrial Services

- Solutions

- Access Planner

- Ammonia Systems Inspection Services

- Asset Integrity Management / Mechanical Integrity

- Cathodic Protection Services

- Corrosion Under Insulation

- Drone & Robotic Inspection Services

- Facilities Piping Management Programs

- High Energy Piping Programs & Solutions

- Hydrogen Industry

- Laboratory Services – Inspection and NDT

- Laboratory Services – Materials Testing & Analysis

- Midstream Integrated Integrity Solutions

- National Board Program

- Non-Intrusive/On Stream Inspection Program

- PHMSA Mega Rule Solutions

- Research and Application Development

- Rope Access for CUPS

- Industries

- Industries Overview

- Aerospace

- Automobile

- Building & Infrastructure

- Chemical

- Food and Beverage

- Insurance & Litigation

- Manufacturing

- Metal Fabrication

- Mining

- Nuclear Power

- Oil & Gas

- Pipeline

- Pipeline Integrity Engineering Services

- Pipeline Integrity Field Services

- Power Generation

- Pulp & Paper

- Rail

- Tanks

- Wind

-

Success StoriesUnparalleled Execution In The Rope Access Light Mechanical Space

Our client, a chemical plant located in east Texas was struggling to have a particular rope access scope of work completed by another provider. When it became clear that progress was falling further behind schedule, and the provider requested more money and time to complete, the client decided to terminate that arrangement. Acuren’s competitive bid was selected to finish the remaining work which included installation of insulation/jacketing on head of vessel, 9 rings, transition and 19 pipe support areas on a 230’ tower utilizing rope access.

-

Success StoriesSolution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Acuren partnered with an energy company to support their TA/Maintenance program. Acuren's access planner worked with the client's planning and execution team to review any work scopes that could be executed via rope access instead of scaffolding to reduce the overall time and cost.

-

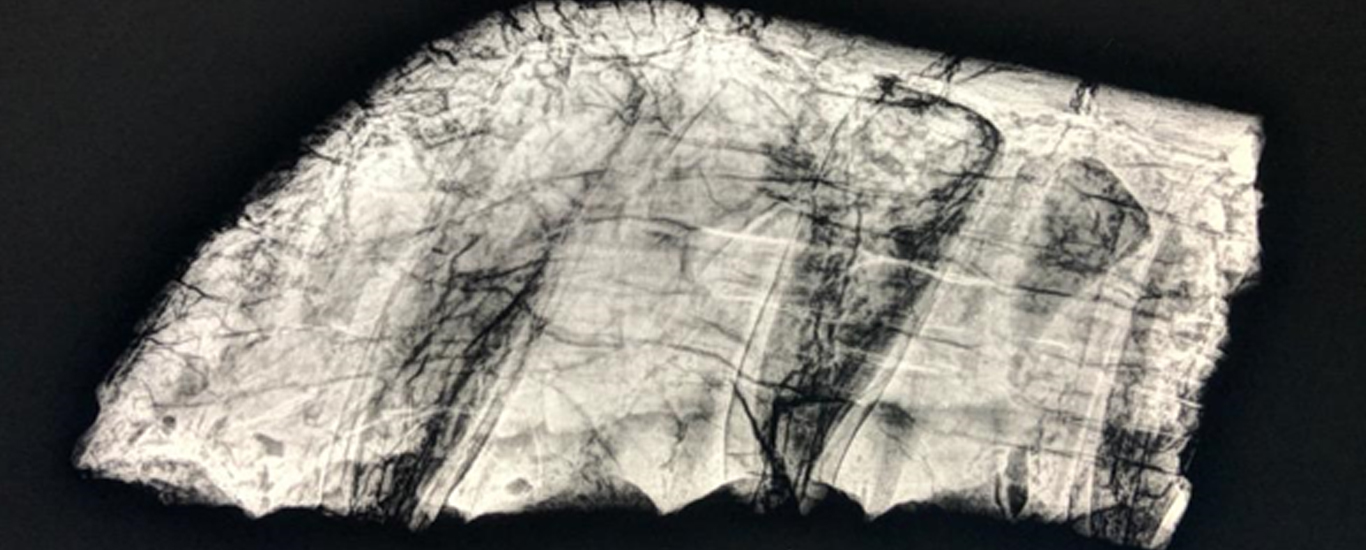

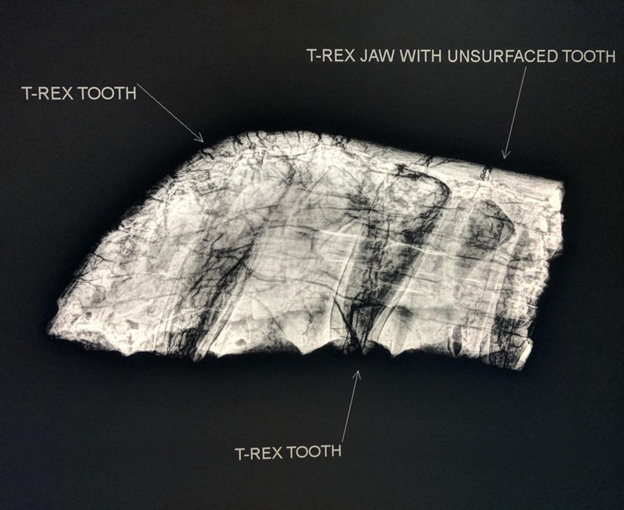

Success StoriesAcuren Helps American Paleo Find and Preserve Fossils

Acuren’s experts partnered with Ohio’s American Paleo to find and preserve fossils using computed radiography (CR). Acuren was tasked with radiographing soft shale, calcite and pyrite, to locate fossils. Our team was able to successfully and safely utilize computed radiography’s benefits over traditional methods to complete the project.

-

Success StoriesSolution Brief - Out of the Box Engineering Solution Saves Months of Time

Engineers, field technicians and NDT experts collaborated to find a suitable technique based on the engineer's unique idea which saved time, cost and increased reliability.

-

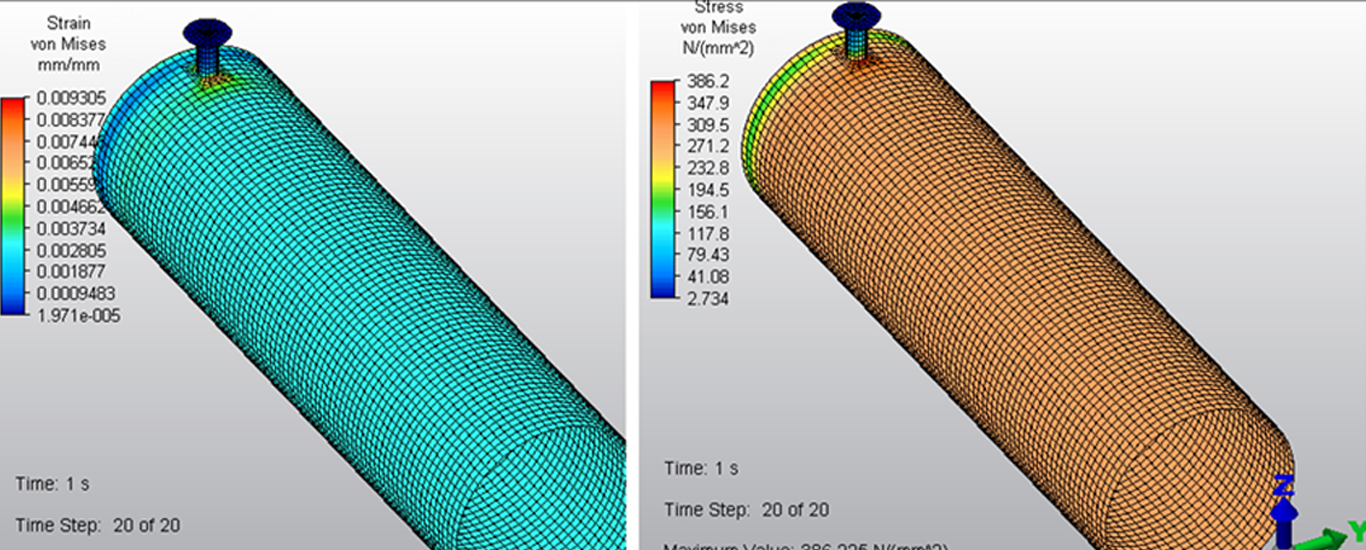

Success StoriesSolution Brief - Emergency Engineering Expertise Restores Critical Asset to Operation

During a turnaround at a gas plant, pressure testing was performed on a sulphur condenser’s (the “vessel”) shell side. The vessel was accidentally overpressured to 5.3 times its MAWP (maximum allowable working pressure). A new vessel would have cost over a million dollars and would have taken over 6 months to be built. Acuren performed Level 3 API 579-ASME FFS-1 Fitness for Service, followed by different NDE techniques, hardness testing and strain gauging during a pressure test. We worked very closely with the regulator and the customer to eventually bring the vessel back to service.

-

Success StoriesAcuren Helps Food Industry Client Prevent Pipe Leaks

Acuren’s Ammonia System Inspection group helped a food industry giant avoid a possible shutdown. Acuren’s experts were tasked with inspecting the pipes and vessels involved in a 75,000 pound ammonia system in Arkansas. The main concern of every ammonia system is corroded pipe that can risk the safety of employees, surroundings, and efficiency of the plant that could ultimately even cause a shutdown. Acuren’s combined testing solution helps clients avoid these risks while meeting all regulatory compliance.

-

Success StoriesUnderside of Bridge Emergency Water Main Repair

There are two 30 inch diameter ¼” wall thickness steel water mains, which run along the underside of the bridge over a river way, that provide major water distribution to the community. The leak locations were difficult to access and on pipe which had an old asbestos coating. Acuren’s engineering and rope access crew provided a safe, economical, and timely repair solution to get the lines back into operating condition.

-

Success StoriesVast Network To Complete Extensive Project On Time and Budget

TEI Analytical Services, Acuren’s sister company, inspected an interstate natural gas transmission pipeline of more than 250 miles of 36” diameter pipe to support pipeline transportation infrastructure needs in Ohio, Michigan and Ontario, Canada. Discover how we delivered on time and on budget.

-

Success StoriesAcuren’s High Temperature Phased Array Outperforms the Competition

Acuren’s HTPAUT specialist team saved the client an estimated $5,000,000 in costs.

-

Success StoriesFlare Stack - Extending Operating Life of Critical Legacy Asset

This oil and gas customer had a 60 year old flare stack with cracking and corrosion that was approaching its end of life. Due to the cracking and corrosion thinning, there was considerable potential for failure for the flare tip and stack pipe. The cost for flare stack replacement was significant and Acuren offered a solution for life extension rather than stack replacement.

-

Success StoriesIntegrated Solutions

Acuren integrated solutions are saving our clients time and money. Acuren safely completed a flare tip replacement and coatings project in Ohio at a fraction of the time and at 40% of the cost. The four-week project incorporated Acuren’s Mechanical, Engineering, and Rope Access Industrial Services.

-

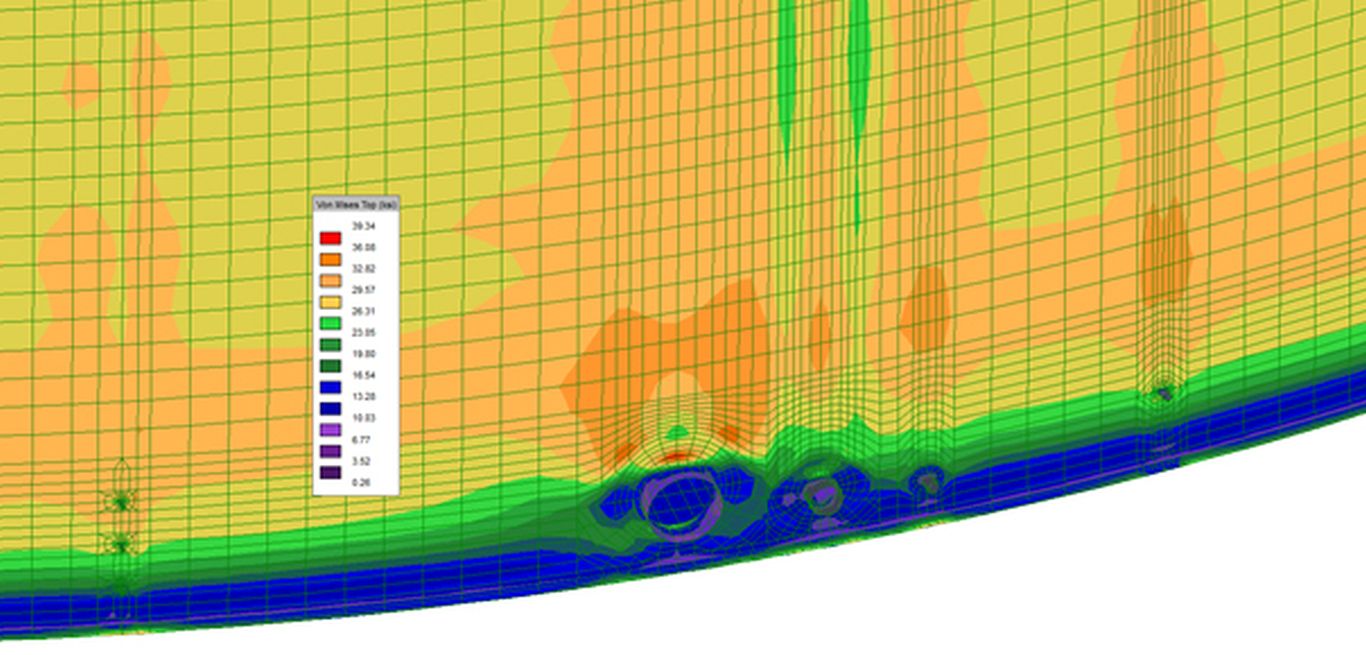

Success StoriesAcuren Tank Solution Saves Client 60 Outage Days and Over $500,000

Historically, a damaged tank, piping or vessel that could not be evaluated successfully using basic standard practices was slated for costly repair, or decommissioning. They turned to Acuren to propose solutions in order to fully understand their options.

-

Success StoriesTank Refurbishment Project Saves Client Over $100,000

When our large refining customer was faced with the requirement to upgrade one of their major crude storage tanks they turned to Acuren’s expertise. We were able to eliminate the hydrostatic test activities through the application of Fitness For Service (FFS) Methodologies as permitted by API 653.

-

Success StoriesRope Access Turns “No Way” Into Project Success

8 day window for the replacement of 2 wear plates in coke chutes for an Athabasca Oil Sands client just north of Fort McMurray.

Testimonial"You guys knocked it out of the park!!! That was an impressive feat and I’m not aware of anyone having done anything like this before. "

Maintenance Supervisor

-

Success StoriesReliability Engineering Services Delivers Cost Savings

Richardson Oilseed is one of Canada’s oldest and largest fully-integrated crushing, refining, processing and packaging operations. In the absence of timely manufacturer support for a critical equipment issue, the full time onsite Acuren Condition Monitoring Specialist was able to diagnose and provide a detailed correction path on a defective trunion bearing.

Testimonial"Acuren’s early detection of the trunnion bearing fault was another win for us. It had allowed us to properly plan the bearing replacement. Not only did we avoid the cost of an emergency repair and production down time, we also avoided additional damage that would have resulted from a catastrophic failure. This is not only a success for Acuren but for all those in the vibration analysis industry given Acuren’s willingness to share their knowledge with regard to this low speed bearing failure. "

Richard Pfeifer| Maintenance Planner

-

Success StoriesRopes Team Saves Thousands on Pump Box Work

During a planned outage ultrasonic testing and visual inspection revealed that a significant portion of the pump box floor either needed to be repaired, or cut out and replaced.

Success Stories

Unparalleled Execution In The Rope Access Light Mechanical Space

Unparalleled Execution In The Rope Access Light Mechanical SpaceOur client, a chemical plant located in east Texas was struggling to have a particular rope access scope of work completed by another provider. When it became clear that progress was falling further behind schedule, and the provider requested more money and time to complete, the client decided to terminate that arrangement. Acuren’s competitive bid was selected to finish the remaining work which included installation of insulation/jacketing on head of vessel, 9 rings, transition and 19 pipe support areas on a 230’ tower utilizing rope access.

Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Solution Brief - Acuren Partners with An Energy Leader to Provide Access SolutionsAcuren partnered with an energy company to support their TA/Maintenance program. Acuren's access planner worked with the client's planning and execution team to review any work scopes that could be executed via rope access instead of scaffolding to reduce the overall time and cost.

Acuren Helps American Paleo Find and Preserve Fossils

Acuren Helps American Paleo Find and Preserve FossilsAcuren’s experts partnered with Ohio’s American Paleo to find and preserve fossils using computed radiography (CR). Acuren was tasked with radiographing soft shale, calcite and pyrite, to locate fossils. Our team was able to successfully and safely utilize computed radiography’s benefits over traditional methods to complete the project.