HRSG Condition Assessment

Acuren provides an experienced set of eyes to examine the health of the gas side and waterside of your Heat Recovery Steam Generator (HRSG). We provide you with an independent assessment of the HRSG condition to assure you of reliable future operation whether you are an owner, operator, or insurer.

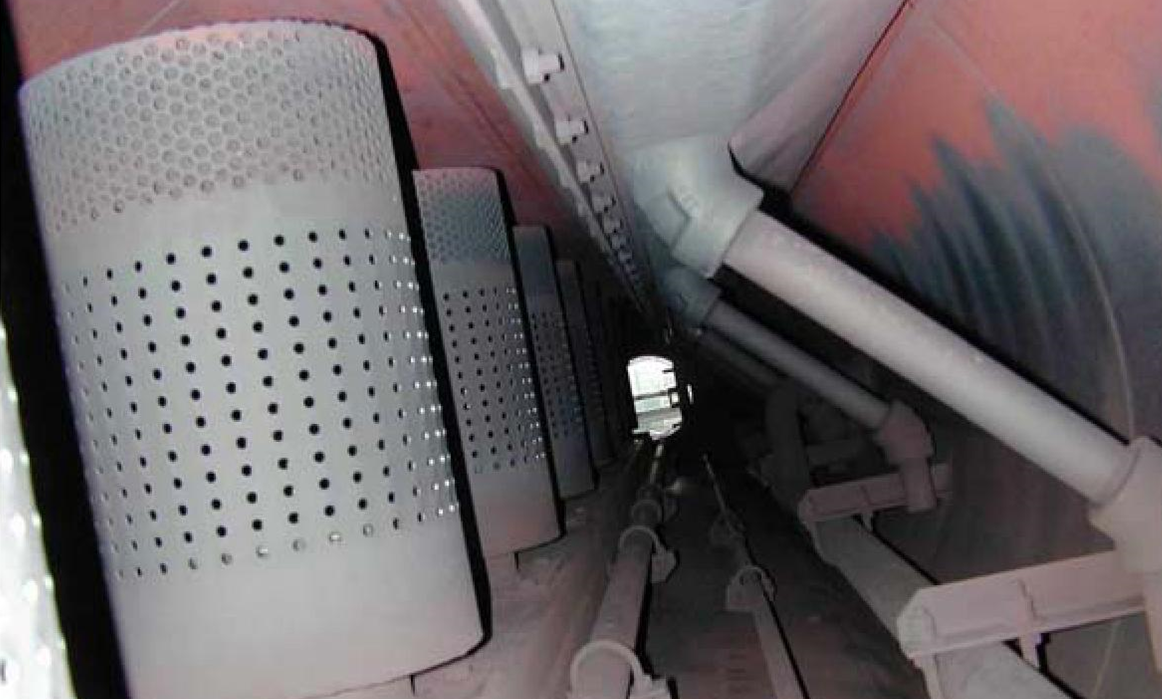

- We examine the gas side of the tubes headers, ductwork, support structure, and duct burners for signs of deterioration from corrosion, cracking, and wear.

- We examine the waterside headers steam drums and risers for corrosion, cracking, FAC, or other damage mechanisms.

- We team with nondestructive testing crews, local or our subcontractors to provide a full condition assessment of your HRSG.

- When problems or failures occur, we provide on-site or in-laboratory metallurgical testing and engineering to get the unit back on line fast.

During the outage, our engineers, water scientists and technicians provide recommendations for immediate repair, as well as focused testing and inspection strategies. Following the outage, a detailed report of our findings will be provided electronically, in hard copy or both. We can also recommend water treatment programs that will prevent waterside corrosion problems and provide recommendations for future repair, replacement, and inspection.

Water Chemistry is Critical

While HRSGs typically lack the heat flux of a standard fossil-fired unit, they are by no means problem-free when it comes to chemistry-related corrosion. In fact, experience has shown that these units seem to have more tube failures than their fossil-fired counterparts. Common causes include flow accelerated corrosion (FAC), under-deposit corrosion (hydrogen damage, gouging, and pitting), and corrosion fatigue. The complex flow patterns, quick starts and stops, and extended lay-up periods all combine to make proper chemical treatment of HRSGs different than the equivalent pressure fossil-fired boiler.

While HRSGs typically lack the heat flux of a standard fossil-fired unit, they are by no means problem-free when it comes to chemistry-related corrosion. In fact, experience has shown that these units seem to have more tube failures than their fossil-fired counterparts. Common causes include flow accelerated corrosion (FAC), under-deposit corrosion (hydrogen damage, gouging, and pitting), and corrosion fatigue. The complex flow patterns, quick starts and stops, and extended lay-up periods all combine to make proper chemical treatment of HRSGs different than the equivalent pressure fossil-fired boiler.

Don’t Patch It, Fix It

When failures do occur, it is tempting to plug the tube and move on, but understanding the failure mechanism, the “why” is critical to understanding the potential for additional failures. A true root cause analysis of the failure is essential to solve the problem completely.

When failures do occur, it is tempting to plug the tube and move on, but understanding the failure mechanism, the “why” is critical to understanding the potential for additional failures. A true root cause analysis of the failure is essential to solve the problem completely.

Acuren has over 40 years of HRSGs, experience in failure analysis in all types of power and industrial boilers, as well as steam and gas turbines. We are experts in the analysis of steam and combustion turbine blade failures. We also understand the process, materials, and operational conditions in combined cycle plants and can work with you to find a way to eliminate failures in the future.

Training

Personnel at many combined cycle plants wear many hats. They operate, maintain, troubleshoot and treat their units. To do it right, they need to know more than just what to do. They need to know the “why to do it”. Acuren can provide on-site training, tuned to your personnel and plant, for a number of areas including water and steam chemistry, nondestructive testing, materials and corrosion issues, and damage repair options.

Personnel at many combined cycle plants wear many hats. They operate, maintain, troubleshoot and treat their units. To do it right, they need to know more than just what to do. They need to know the “why to do it”. Acuren can provide on-site training, tuned to your personnel and plant, for a number of areas including water and steam chemistry, nondestructive testing, materials and corrosion issues, and damage repair options.

| RELATED SERVICES | ||||

|---|---|---|---|---|

| Power Generation Laboratory Services – Materials Testing NDT & NDE High Energy Piping Programs & Solutions |

||||