![]()

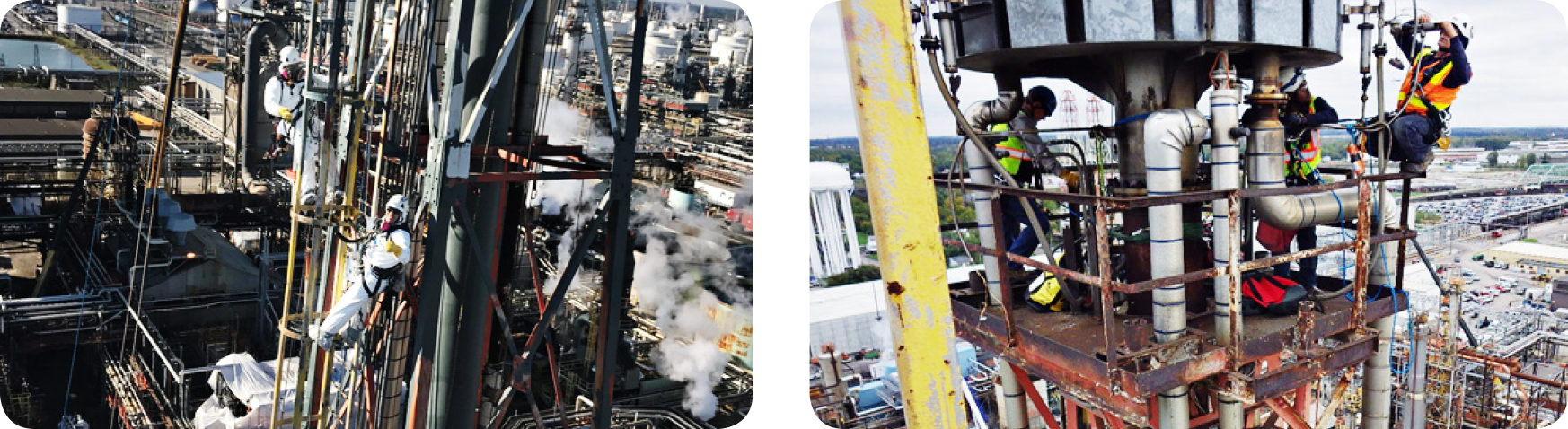

Acuren Safely Completed a Flare Tip Replacement & Coatings Project in Ohio

The four-week project incorporated Acuren’s Mechanical, Engineering, and Rope Access Industrial Services to replace an existing flare tip at a refinery, including weld repairs and coatings.

The project utilized rope access to remove the existing flare tip and install a new one, weld repairs on decking, hand tool cleaning of structure, and removal and collection of lead paint, followed with primer, mid-coat, and top coat application.

Acuren completed the job in fraction of the time and at 40% of the cost.

Traditionally, scaffolding is used to replace the flare tip. The time to erect scaffolding, replace the flare tip, and properly coat the structure usually exceeds that of a 30-day turnaround. Acuren was able to replace the flare tip in three days allowing time for welding repairs, structure cleaning/lead abatement, and coatings. Costs estimates for scaffolding were estimated at $800,000. Acuren was able to perform the project including labor, materials, and equipment for under what it would cost for the scaffolding alone saving the client both time and expense.

Acuren has one of the industry largest force of Rope Access subjects matter experts local to almost every project. Acuren’s integrated services provide solutions to the client’s toughest jobs. Our engineers develop efficient plans utilizing Acuren’s countless resources to save clients time and money that lead our experts to complete complex projects under budget, in less time and safer. Every year fatalities occur from erecting and working from scaffolding. Acuren has fewer people at risk for less time with zero footprint allowing traffic and mobilization to occur where scaffolding would be. Acuren Rope Access teams have a commitment to safety with a 5-year incident rate of 0.00.

To learn more about Acuren’s personalized solutions contact us today 1-800-218-7450.