Facilities Piping Management Programs

WHY PIPING PROGRAMS? Piping Leaks? Piping Failures? Losing Revenue and Time? Acuren has piping programs specifically tailored to address your above-ground facility piping program needs.

Facility Piping Management Programs

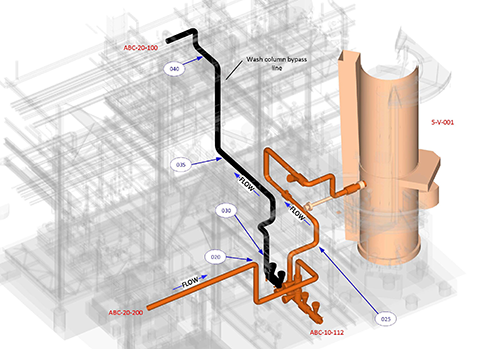

- Experienced Engineers and API inspectors develop piping management programs to ensure regulatory and insurance compliance

- Obtain missing key information (Isometrics, P&ID’s, PFD’s) that prevents you from executing your piping program

- Assess as standalone or integrated program:

- Small bore piping

- Dead Legs

- Structural supports

- Flange inspections

- High Energy Piping

- Corrosion Under Insulation

- Corrosion Under Pipe Supports

- Buried piping systems

- Pipeline Integrity Support

| WHY ACUREN? |

|---|

|

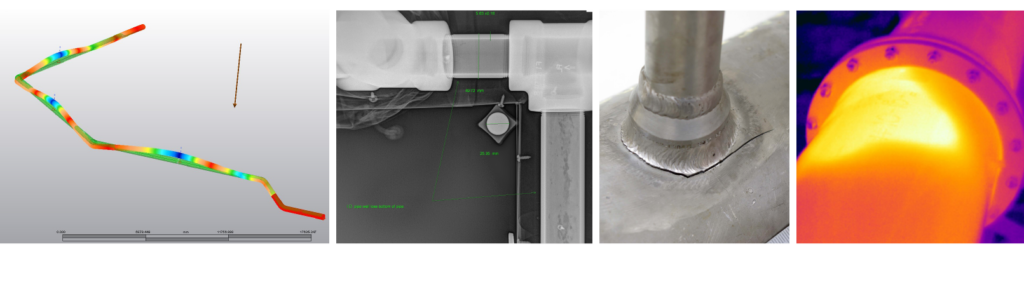

NDE Methods For Piping Inspection

Acuren knows where to look for the relevant damage mechanisms utilizing the latest technologies:

- Moisture Detection Imaging (MDI) – Compton Backscatter

- Radiographic methods: Real Time Radiography (RTR), Computed Radiography (CR), Digital Radiography (DR), traditional

- Advanced Ultrasonic Inspections (PAUT, TOFD, AUT, Guided Wave (GUL), flange scanning)

- Infrared Thermography (IR)

- Laser Scanning and mapping

- Ultrasonic Thickness (UT) measurements

- Pulsed Eddy Current (PEC)

- Ground Penetrating Radar (GPR)

- HawkEye External Corrosion Screening Tool

-

- Indirect inspections of facility piping (CIPS, ACVG, DCVG, ACCA)

- Locate areas with coating anomalies and deficient CP

- Other traditional NDE methods

Engineering

- Perform failure modes and effects analysis (FMEA)

- Develop integrity operating windows (IOW’s)

- Create and implement Risk Based Inspection (RBI) programs

- Perform equipment failure analysis

- Fitness for service assessments (API 579)

- Piping Stress and finite elemental analysis (FEA)

- Pipeline Integrity Engineering Services

Cathodic Protection

Cathodic Protection (CP) services for buried piping. Click here for full list of CP Services.

-

- Hawkeye External Corrosion Screening Tool

- Indirect inspections of facility piping:

- Close Interval Potential Survey (CIPS)

- Alternating Current Voltage Gradient (ACVG)

- Direct Current Voltage Gradient (DCVG)

- Alternating Current, Current Attenuation (ACCA)

- Locate areas with coating anomalies and deficient CP

- Ground penetrating radar (GPR)

- Indirect inspections of facility piping:

- Hawkeye External Corrosion Screening Tool

Rope Access & Industrial Solutions

Rope Access Methods:

- Where scaffold or other means of access are not practical, Acuren can utilize rope access means to assess CUI (eg. modular piping, towers, stacks)

- All inspection and NDE and industrial services can be provided from ropes

Industrial Services:

- Journeyman Insulators

- Insulation removal/repairs

- Insulation installation

- Asbestos abatement

- CML ports installed

- Fireproofing

- Repairs / Replacement

- Welding and Fabrication

- Pipefitting

- Pressure cleaning and blasting

- Coatings: NACE Inspectors, coating removal and recoating

- Electrical and instrumentation

- Rope Access Industrial Services

Drone and Robotic Inspection Services

Acuren utilizes remotely piloted aerial systems and robotic inspection cameras to aid in piping programs.

- Perform internal and external API inspections

- Ultrasonic thickness testing with robotics and drones

- Perform pipe hanger surveys

- Thermal imaging / infrared scanning

- Emission detection

- 3D Lidar scanning and photogrammetry

- Create a “Digital Twin” of your facility

- Drone and Robotic Inspection Services

Improve Your Facility Piping Management With Acuren

Our team of engineers and API inspectors are here to help you develop piping management programs that meet regulatory and insurance compliance rules. Contact us online to get in touch with an Acuren representative about our services, or call us at 1-800-218-7450.