- About

- About Overview

- Vision & Values

- Leadership Teams

- Corporate

- Canadian Operations

- United States Operations

- Service Line

- Safety

- Quality

- Environment

- Sustainability

- Indigenous Policy

- Hellier Training

- Applied Inspection

- Engineering

- Engineering Overview

- Field Engineering

- Field Engineering Overview

- Ferrite Testing

- Hardness Testing

- Metallurgical Replicas

- Optical Emission Spectroscopy (OES)

- Positive Material Identification (PMI)

- Materials Testing & Analysis

- Materials Engineering

- Metallurgical Condition Assessment

- Steam Cycle Chemistry Services

- STRAP – Steam Turbine Risk Assessment Program

- Support for Industrial Insurers and Independent Adjusters

- Water Treatment Technologies Services

- Reliability Engineering

- Vibration Analysis

- Inspection

- Inspection Overview

- Advanced NDE/NDT

- Moisture Detection Imaging (MDI)

- Non-Intrusive/On Stream Inspection Program

- Phased Array Services

- Time of Flight Diffraction Technique (ToFD)

- Tube to Tube Sheet Weld Inspection

- NDE/NDT

- Visual Inspection (VT)

- National Board Program

- Drone & Robotic Inspection Services

- Lab Services – Inspection & NDT

- Rope Access for Inspection

- Inspection Training

- Rope Access Industrial Services

- Solutions

- Access Planner

- Ammonia Systems Inspection Services

- Asset Integrity Management / Mechanical Integrity

- Cathodic Protection Services

- Corrosion Under Insulation

- Drone & Robotic Inspection Services

- Facilities Piping Management Programs

- High Energy Piping Programs & Solutions

- Hydrogen Industry

- Laboratory Services – Inspection and NDT

- Laboratory Services – Materials Testing & Analysis

- Midstream Integrated Integrity Solutions

- National Board Program

- Non-Intrusive/On Stream Inspection Program

- PHMSA Mega Rule Solutions

- Research and Application Development

- Rope Access for CUPS

- Industries

- Industries Overview

- Aerospace

- Automobile

- Building & Infrastructure

- Chemical

- Food and Beverage

- Insurance & Litigation

- Manufacturing

- Metal Fabrication

- Mining

- Nuclear Power

- Oil & Gas

- Pipeline

- Pipeline Integrity Engineering Services

- Pipeline Integrity Field Services

- Power Generation

- Pulp & Paper

- Rail

- Tanks

- Wind

Home Success Stories Reliability Engineering Services Delivers Cost SavingsReliability Engineering Services Delivers Cost Savings

Summary

Richardson Oilseed is one of Canada’s oldest and largest fully-integrated crushing, refining, processing and packaging operations. In the absence of timely manufacturer support for a critical equipment issue, the full time onsite Acuren Condition Monitoring Specialist was able to diagnose and provide a detailed correction path on a defective trunion bearing. This included a complete pinion alignment within a planned outage window resulting in eliminating an unplanned outage with minimal equipment down time. Left undiagnosed, this would have resulted in a critical system failure, an unplanned outage, collateral damage and significant costs.

The Challenge – Leveraging Technology to Deliver Results

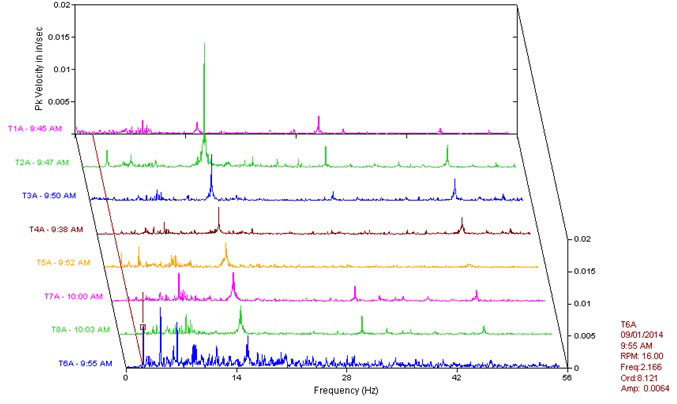

Utilizing mechanical Ultrasound an unusual popping and rubbing sound was identified at this cooker location and further investigation revealed that the rollers were making contact, and rubbing at the guard. Upon adjustment of the guard, the identified popping and rubbing became more distinct prompting further evaluation utilizing Vibration and Infrared Analysis. To complicate matters the manufacturer was unable to provide any bearing specifications, thus requiring more in-depth analysis to determine the root cause of the problem.

The Methodology – Analytical Problem Elimination

Once Vibration and Infrared data were collected, the results were reviewed by the Acuren team of reliability experts. The infrared data indicated a difference in temperature in excess of 5.7 degrees Celsius between known good and suspect bearings. In addition, the pinion shaft run-out was measured and results indicated a significant shaft deflection leading to the realization that the shaft was also bent.

The Value – Significant Costs Avoided

The hard dollar cost of this repair, including lost production was approximately $750,000. The bearing replacement and pinion alignment required 9 hours to complete with the equipment being restored to full operational capacity within 13 hours. Had this critical issue gone undetected, an unplanned repair would have taken an estimated 14 days with a cumulative conservative cost estimate, and negative impact on the bottom line, of $19.5 Million.

"Acuren’s early detection of the trunnion bearing fault was another win for us. It had allowed us to properly plan the bearing replacement. Not only did we avoid the cost of an emergency repair and production down time, we also avoided additional damage that would have resulted from a catastrophic failure. This is not only a success for Acuren but for all those in the vibration analysis industry given Acuren’s willingness to share their knowledge with regard to this low speed bearing failure. "

Richard Pfeifer| Maintenance Planner