Featured Success Stories

Moving RNG to Market with Natural Gas Expertise

A Midwestern farmer embarked on a groundbreaking Renewable Natural Gas (RNG) project, collaborating with experienced pipeline system engineers to establish a connection to a traditional natural gas pipeline system. Acuren played a pivotal role, serving as the designer of the interconnect station and pipelines, providing a comprehensive design package and consulting on project implementation.

Featured Success Stories

Combatting Flange Face Erosion and Corrosion with Advanced PAUT Solutions

In oil and gas operations, where unsafe practices can lead to costly failures, flange face erosion and corrosion pose critical threats. These issues compromise refinery infrastructure, turning small flaws into major liabilities. With each flange connection vital to pipeline integrity, failures can cause leaks, unplanned downtimes, and lost revenue. This case study highlights strategies to combat these hidden dangers, ensuring safety, efficiency, and uninterrupted energy flow for global markets.

Featured Success Stories

Solution Brief – Acuren Partners with An Energy Leader to Provide Access Solutions

Acuren partnered with an energy company to support their TA/Maintenance program. Acuren’s access planner worked with the client’s planning and execution team to review any work scopes that could be executed via rope access instead of scaffolding to reduce the overall time and cost.

Featured Success Stories

Acuren Helps American Paleo Find and Preserve Fossils

Acuren’s experts partnered with Ohio’s American Paleo to find and preserve fossils using computed radiography (CR). Acuren was tasked with radiographing soft shale, calcite and pyrite, to locate fossils. Our team was able to successfully and safely utilize computed radiography’s benefits over traditional methods to complete the project.

Featured Success Stories

Solution Brief – Emergency Engineering Expertise Restores Critical Asset to Operation

During a turnaround at a gas plant, pressure testing was performed on a sulphur condenser’s (the “vessel”) shell side. The vessel was accidentally overpressured to 5.3 times its MAWP (maximum allowable working pressure). A new vessel would have cost over a million dollars and would have taken over 6 months to be built. Acuren performed Level 3 API 579-ASME FFS-1 Fitness for Service, followed by different NDE techniques, hardness testing and strain gauging during a pressure test. We worked very closely with the regulator and the customer to eventually bring the vessel back to service.

Featured Success Stories

Underside of Bridge Emergency Water Main Repair

There are two 30 inch diameter ¼” wall thickness steel water mains, which run along the underside of the bridge over a river way, that provide major water distribution to the community. The leak locations were difficult to access and on pipe which had an old asbestos coating. Acuren’s engineering and rope access crew provided a safe, economical, and timely repair solution to get the lines back into operating condition.

Hydrostatic Test Establishes New MOP for 100-mile Pipeline

Faced with anomaly-related pressure reductions and ambiguous ILI results, a client turned to Acuren's engineering team for a comprehensive integrity solution. Acuren managed nitrogen purging, anomaly cutouts, spike and hydrotesting, and pipeline restoration, securing a five-year reassessment interval and re-establishing MOP. Through strategic planning and contingencies, the project exceeded expectations, finishing early and under budget.

Managing System Wide Depth of Cover to Reduce Risk to Critical Assets

Implementation of a Closed System Mitigates the Possibility of an Emergency Event While Also Solving an Odor Issue

Preparing a Valuable Asset for the Next Chapter of Service

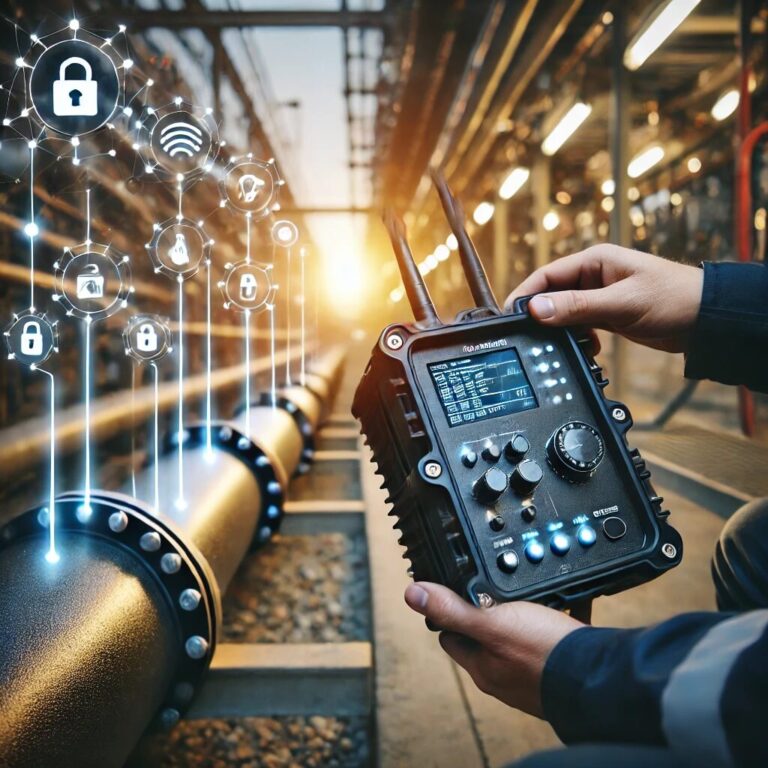

Installing a Communications Gateway to Enhance Pipeline Cybersecurity