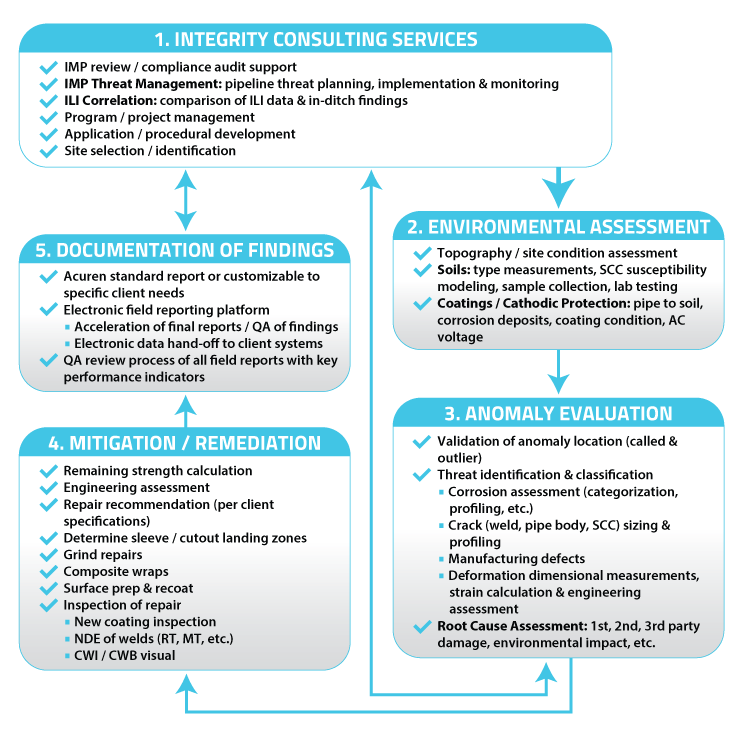

Comprehensive Services

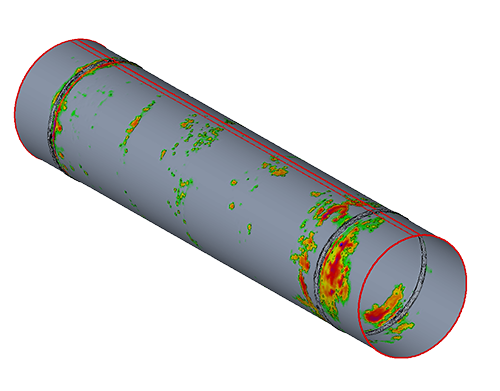

Failure Analysis & Material Evaluation Of Pipelines

Owners manage the integrity of above-ground and buried pipelines with numerous systems and processes. However, there can be unforeseeable circumstances or system breakdowns which precipitate failures of piping and auxiliary equipment. Acuren’s highly experienced engineers can perform failure analysis, evaluate material properties, suggest alternatives to materials, testing/monitoring procedures to help Owners prevent future occurrences. As part of the failure investigation / product evaluation, engineers assess the components in the field and/or laboratory which may include:

- Detailed analysis of pipeline fracture surface to determine failure mode/mechanism

- Determine if pipe meets the specified mechanical and chemical properties with laboratory testing

- Optical microscopy and scanning electron microscopy to evaluate material microstructure, flaws and fracture surfaces

- Determine presence of bacteria involved in microbiologically influenced corrosion (MIC)

- Identify type of corrosion scales and foreign debris using x-ray diffraction (XRD) or energy dispersive x-ray (EDX) spectroscopy

- Perform burst testing of pipe to predict failure pressures, strain and fracture mode

- Crack Tip Opening Displacement (CTOD) testing to determine critical allowable flaw sizes in pipe welds

- Provide independent failure analysis and reports for regulatory bodies

Committed To Excellence

Committed to delivering a higher level of reliability, Acuren provides an unrivaled spectrum of services to support the safe operation of industrial assets. Acuren’s commitment to safety, quality and professionalism spans four decades. We have programs to manage risk in all environments as well as robust programs to manage resources, equipment, personnel, environmental practice, audit, reporting, safety and customer stewardship expectations. Our expertise in weld inspection, crack sizing, corrosion mechanisms, and deformation has made us the first call for natural gas and liquid pipeline operators across all climates.| Our goal is to provide pipeline integrity programs, services and threat management programs to meet the increasing demands of our pipeline customers. Acuren has dedicated years of training and resources to ensuring the value we deliver through our pipeline integrity programs far exceeds that of our competition. | ||||

|---|---|---|---|---|

| Execution Excellence: dedicated pipeline integrity operation ensuring safety, quality and scope execution excellence Specialization: technicians specifically trained and dedicated to supporting pipeline integrity programs rather than general NDE technicians Damage Mechanism Capabilities: technicians have specific and intimate damage mechanism identification capabilities Scalability: we have a pipeline integrity technician pool that spans North America Multiple Disciplines: our pipeline integrity technicians have experience in multiple disciplines: coatings, cathodic protection, soils geology, inline inspection and NDE Program Management: verification of log data, interpretation of inspection results and threat management | ||||

Dedicated Personnel

- We employ technicians that are trained, capable, and certified in:

- NACE

- CWI/CWB

- PAUT

- Corrosion Mapping

- Guided Wave

- TOFD

- OES

- PEC

- MT

- PT

- Better understanding of pipeline defect mechanisms resulting in more accurate anomaly evaluations

- Better productivity / efficiency in ditch reducing overall cost per dig

- More consistent and higher quality reports

- Inhouse Operator Qualification management (EWN, ISN/NCCER, Veriforce) allows Acuren to ensure inspectors are certified and qualified for tasks performed

Centralized Management

- Single point of contact

- Consistent invoicing

- Ease of scheduling

- Complimentary services

SCC Threat Management

- Multiple inspection methods

- 15+ years performing assessments

- Soils modeling / survey integration

Full Range Of Solutions

- NDE on Pipeline Approach

- Conventional NDE inspection techniques (e.g. MT, UT Straight Beam, Pit Gauging) on pipeline defects

- Provide results to 3rd party / company personnel for assessment

- Hybrid Approach

- Broader, more complex inspection methods with more encompassing report to include additional components (such as soils, coatings, cathodic protection system readings, etc.)

- Root Cause Assessment

- Analytical process / procedure to assess defect and attempt to identify root cause (isolated or more systemic damage mechanism)

- Up to 3rd party engineering / assessment

Investment In Accuracy, Repeatability, & Efficiency

- Pipeline specific training program (nomenclature, damage mechanisms, manufacturing methods, etc.)

- Reporting platforms (efficiencies, quality, timeliness of reports)

- Client specific customization, reduction of transposition errors, reduced report generation time, systematic QA checks, client dashboards

SPECIFIC SERVICES

RT

Magnetic Particle Services

Dye Penetrant Services

Ultrasonic Services

Eddy Current Services

Flux Leakage

Thermal Inspection

Automated Ultrasonic

Advanced Ultrasonic

Specialized Techniques

Advanced Radiographic

|

Specialized Tubing Inspections

Boiler Life Assessment/Materials EngineeringPipeline Services

Valve Leak DetectionFugitive EmissionsGround Penetrating RadarMaterials Engineering Services

Materials Laboratory ServicesRope Access InspectionCalibration ServicesWelder TestingPipeline Integrity Services

Moisture DetectionTraining SchoolsVisual Inspection

Software Development

Autocad/Field SketchingProcedure Development |

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →