Failure Analysis

When a breakdown occurs, the actual cause of the failure may not be apparent or may be different than what seems likely.

Failure Analysis

- Minimize Outages Caused by Equipment Failures

- Correct Characterization of Equipment Failures

- Discover the Root Cause and Determine the Best Solution

- Would investment in a higher grade component pay off?

- Should the part be redesigned or simply replaced?

- Is a cost-effective repair available?

- Should a repair be considered good-as-new or only a temporary solution?

- Would a new material last longer?

What’s Involved?

What’s Involved?

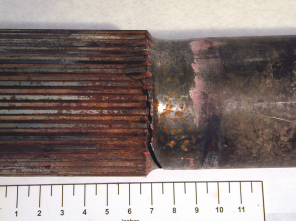

A failure analysis can have three broad objectives—determining mode, cause, or root cause. Failure mode may be determined on-site or in the laboratory, using methods such as fractography, metallography, and mechanical testing. Some common failure modes are fatigue, tensile overload, and stress rupture.

Failure cause is determined from laboratory studies and knowledge of the component, its loading, and its environment. Comparative sampling or duplication of the failure mode in the laboratory may be necessary to determine the cause.

Root failure cause is determined using knowledge of the mode, the cause, and the particular process or system. Determining the root failure cause may require complete information about the equipment’s design, operation, maintenance, history, and environment.

Conducting an Analysis

Conducting an Analysis

Acuren performs failure analyses in the field, the laboratory, or both. On-site analysis may involve photography, wreckage position documentation, preservation and identification of pieces, eyewitness interviews, record and blueprint review, in-place metallography and replication, hardness testing, and sampling. In-place metallography permits on-site assessment of the damage without destructive sampling.

Metallography is particularly powerful when combined with typical nondestructive examination (NDE) methods such as ultrasonic testing, eddy current, magnetic particle testing, or liquid penetrant testing.

A typical failure analysis might include fractography, metallography, and chemical analysis. The failed component is examined and its condition documented. If appropriate, scale or deposits are collected and any fracture surface features are documented. A scanning electron microscope (SEM) is often used to evaluate fracture surfaces for material defects, determine fracture modes, and measure fracture features and particles precisely.

Our engineers also use energy dispersive X-ray spectroscopy (EDS) to identify elemental constituents in contaminants, corrosion products, and complex microstructures.

A metallographic evaluation of the failed part can identify thermal, mechanical, and corrosion-related deterioration. This evaluation will also show whether deterioration was general or localized.

Expert Assessments

Acuren can expertly assess what a thorough analysis will require, then participate as either a principal investigator or as part of an investigative team.

Our engineers are familiar with the equipment and processes used in utility plants, refineries, pulp and paper mills, chemical plants and many other industrial facilities. By systematically identifying, defining, and understanding a failure, we can provide improved equipment reliability and safety for your facility. Acuren offers:

Acuren can expertly assess what a thorough analysis will require, then participate as either a principal investigator or as part of an investigative team.

Our engineers are familiar with the equipment and processes used in utility plants, refineries, pulp and paper mills, chemical plants and many other industrial facilities. By systematically identifying, defining, and understanding a failure, we can provide improved equipment reliability and safety for your facility. Acuren offers:

- Responsiveness — we’re always on call and can be at your site in less than 24 hours

- We have extensive experience in many diverse disciplines

Independent Third-Party Laboratory Services

As an independent third-party laboratory, Acuren has performed tens of thousands of formal multi-party investigations, accident investigations, and failure analyses. We provide litigation support to insurance and legal industries by way of documentation reviews, material evaluations, laboratory testing, technical reporting, and expert witness testimonies.| RELATED SERVICES | ||||

|---|---|---|---|---|

| Laboratory Services – Inspection & NDT

NDT & NDE

High Energy Piping Programs & Solutions

Insurance & Litigation

QUICK LINKS

QUICK LINKS

|

||||

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →

Conducting an Analysis

Conducting an Analysis