Acoustic Emission Testing

Reliable Structural Defect Detection

Acoustic Emission (AE) testing is a proven and preferred method for detecting structural defects quickly and reliably. By using sensors to identify high-frequency signals generated by stressed defects, AE testing offers efficient, non-destructive evaluation during structural proof tests and plant operations.

This advanced technique helps locate minor damage before failure occurs, with results analyzed by our skilled technicians. By measuring emission rates, our experts determine defect locations and initiate procedures established during prequalification, which may include additional inspection methods for defect remediation. Unlike traditional NDT, AE testing provides valuable insights into the severity and origin of structural issues.

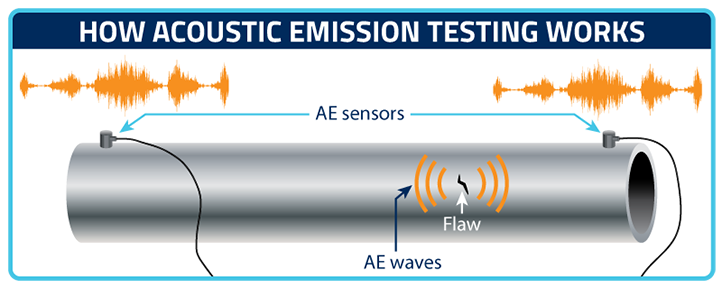

How Acoustic Emission Testing Works

AE testing captures high-frequency sound waves emitted by structural defects under stress. These emissions are analyzed to pinpoint defect locations and assess their severity, ensuring timely and precise action.

Common Defects Detected Via Acoustic Emission Testing

- Cracks

- Corrosion/pitting

- Hydrogen-induced defects

- Leaks

- Stress Corrosion Cracking (SCC)

Advantages of AE Testing

- Early Detection: Identify defects before they escalate into critical issues.

- Comprehensive Assessment: Provides a 100% global evaluation of large structures.

- Operational Flexibility: Monitors structures during real operational conditions.

- Cost Efficiency: Reduces or eliminates downtime.

- Noninvasive: Requires no disruption to operations.

AE Testing Method Applications

- Metal and FRP pressure vessels, piping, and tanks

- Infrastructure, including highway bridges

- Reactor and cool-down piping

- Pre-service and post-repair hydro-testing

- Aerial man/material lifts

- Seamless tube bundles and trailers

- Structural Health Monitoring (SHM)

| WHY ACUREN? |

|---|

Acuren offers a comprehensive, turnkey solution for your Acoustic Emission (AE) testing needs, supported by an extensive network of 90+ locations. Our services are designed to provide seamless execution, leveraging decades of expertise and a broad range of complementary capabilities, including:

|

Stay ahead of structural failures with Acuren’s Acoustic Emission Testing.

Detect cracks, corrosion, and other defects before they become critical – without interrupting operations. Our advanced AE testing delivers real-time insights, comprehensive evaluations, and unmatched precision to keep your assets safe and reliable. Trust Acuren to protect your operations with industry-leading expertise and innovative solutions.

Download Brochure

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →