Laser Scanning

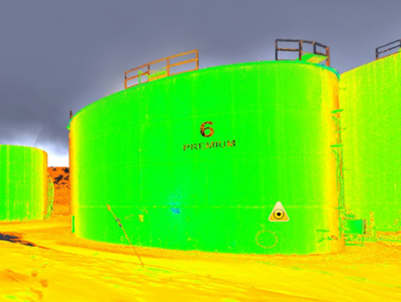

Laser Scanning offers an excellent method for assessing many of the factors required for an API 653 internal or external inspection.

Laser Scanning

Why Laser Scanning?

- Laser Scanning offers an excellent method for assessing many of the factors required for an API 653 internal or external inspection

- Using laser scanning technology, API 653 inspectors are able to complete their inspections more quickly and more accurately

- Laser scanning collects millions of data points. The high quality data provides a much greater range of reporting options, including impressive visual presentations and rich data sets for doing advanced analysis such as FEA.

Fast, Accurate, Cost-Effective Tank Evaluation

Accuracy

- Accuracy +/- 0.7 mm or 0.0027 in at 15 m

- Max Range 120 m

- Accuracy +/- 0.05 mm or 0.002 in

- Max Range 0.3 m or 12 in

- Tank Concerns Collects more data

- Faster

- More accurate

- Verifiable, repeatable, reliable results

- More analysis and reporting options

- Visual results

- Export data to other applications – Excel, Auto Desk, Solid Works

- Ability for analysis of asset after it has been put back in service

- Corrosion

- Edge settlement

- Shell deviations

- Damage monitoring

- Secondary containment volume

- Planar tilt

- Ovality

- Bulges

- Dents

VERTICAL DEVIATION PROFILES

Vertical deviation profiles can be presented visually, extracted at very fine intervals and exported to Excel for further assessment. Different colors highlight the deviations, clearly indicating problem areas. Sections can be exported quickly, providing answers in 15 – 30 minutes.

Significant vertical deviations are generally indicative of abnormal operating conditions. Using the laser allows quick and finite determination of the extent of the deviations.

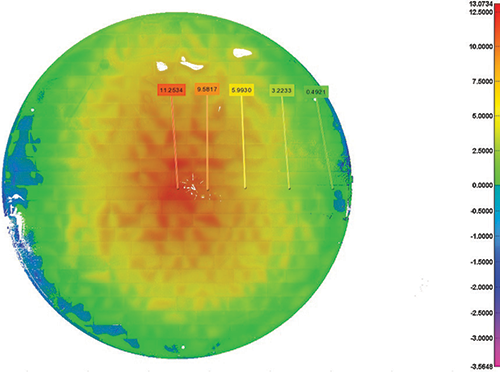

FLOOR DEVIATIONS & EDGE SETTLEMENT

Laser scanning provides settlement measurements and a visual representation of floor deviations in the tank bottom. Additional sketches show the layout of measurement points. Deviations and edge settlement are presented via charts and sketches.

The laser scan of this tank floor shows a limited amount of edge settlement as highlighted in blue.

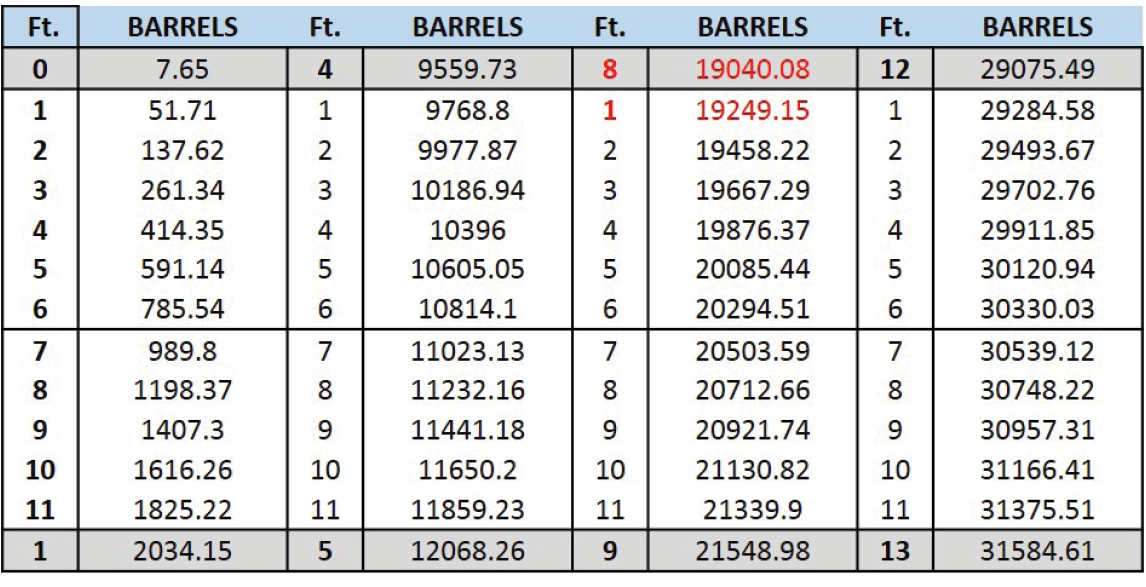

STRAPPING TABLES

A strapping table demonstrates the volume of fluid in a tank at a given height. The laser takes into account that no tank is perfectly round and/or concentric and provides precise volumetric measurements of volume at a specific height. Red text indicates critical zones.

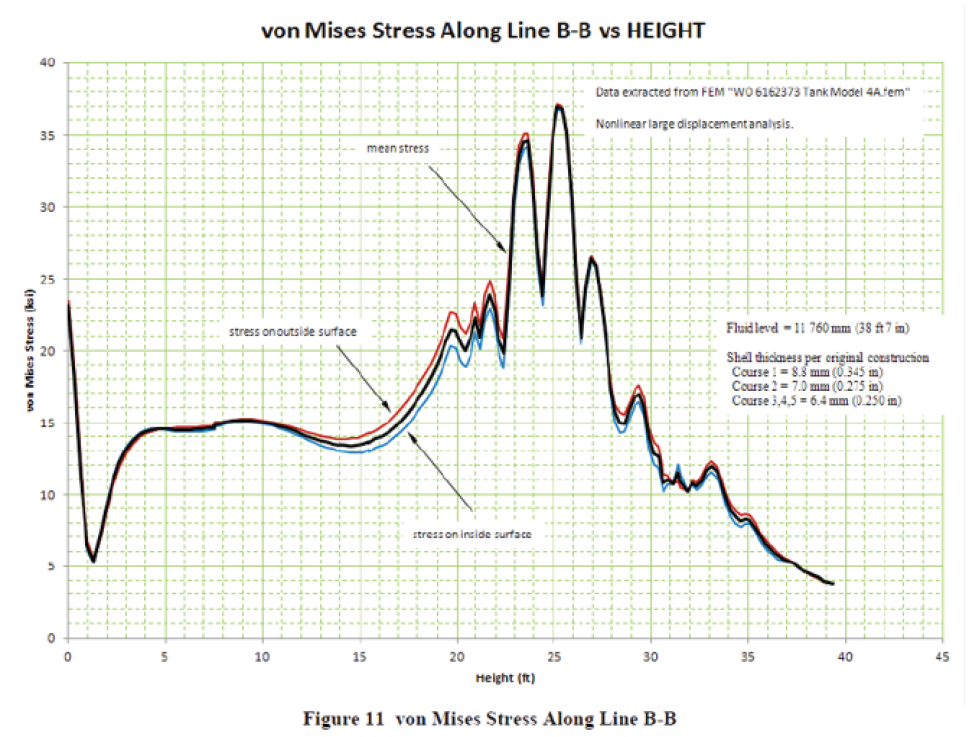

FEA ANALYSIS ON TANKS

FEA analysis using laser data can precisely model tank bulges and accurately predict fit for service life cycle.

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →