Our Experience

in Numbers

Materials testing helps Acuren reduce risk, extend material life, and ensure safer processes.

At Acuren, we have designated centers of expertise for conducting specialized testing. Our technical libraries contain an extensive collection of materials standards, both current and historical, for evaluating test results. Our extensive professional engineering experience is supported by our NADCAP and ISO/IEC 17025 accreditations.

Leading Provider of QC/ QA Services

Acuren is the world’s leading provider of Quality Control / Quality Assurance testing and inspection laboratory services to a variety of manufacturing companies that require the highest level of technical competency, while delivering unmatched productivity and efficiency.

Work with Us- Chemical Analysis

- Polymers & Plastics Testing

- X-Ray Diffraction (XRD)

- Mechanical Testing – Metals

- Coating Inspection & Testing

- Corrosion Testing

- Sour Gas Corrosion Testing

- Machine Shop Services

- Laser Scanning

- Optical & Scanning Electron Microscopy

Chemical Analysis

Chemical analysis identifies material grade and compliance using techniques like ICP, OES, LECO, and ion chromatography.

Polymers & Plastics Testing

DSC, FTIR, TGA, hardness, impact, specific gravity, flexural strength, flammability, and more.

X-Ray Diffraction (XRD)

XRD analyzes solid samples to identify and quantify crystalline compounds, useful for foulants and corrosion scales.

Mechanical Testing – Metals

Tensile testing (-40°F to +2000°F), CTOD, Charpy impact, bend, proof load, burst, stress rupture, and hardness testing.

Coating Inspection & Testing

NACE-certified inspectors perform adhesion, bond strength, coating weight, and thickness testing.

Corrosion Testing

Bacterial testing, accelerated corrosion testing (NACE/ASTM), autoclave simulations, Avesta cells, NACE cells, and salt fog.

Sour Gas Corrosion Testing

Metal components in sour environments risk corrosion or cracking; NACE/AMPP tests evaluate resistance to cracking mechanisms effectively.

Learn MoreMachine Shop Services

EDM, mechanical test sample prep, heat treating, and UT calibration block manufacturing.

Laser Scanning

Assessment of corrosion features & dents, 3D mapping, CAD, geometric profiling, dimensional analysis, and Digital Twin creation.

Learn MoreOptical & Scanning Electron Microscopy

Precision sample prep, up to 200,000X magnification, EDX for chemical ID, fracture analysis, failure mode determination, and more.

Comprehensive Materials Testing

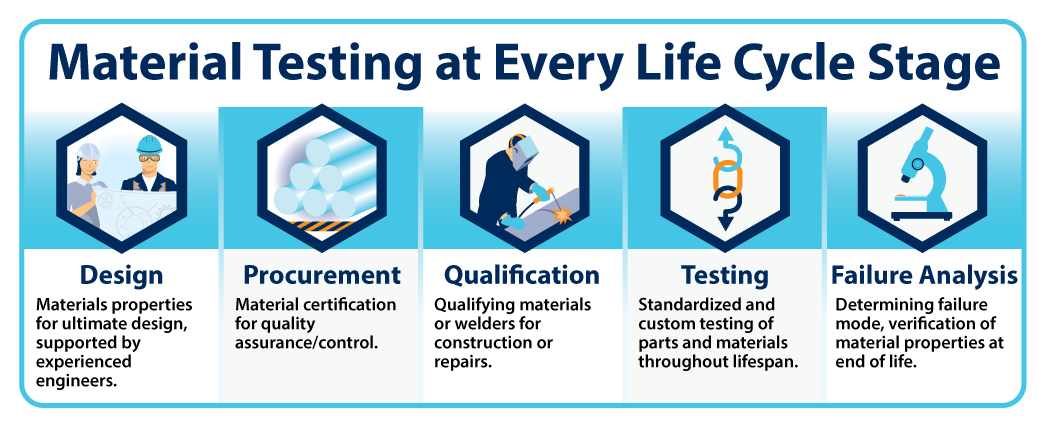

Defining material properties for optimal design with experienced engineers, ensuring quality through material certification and control, qualifying materials and welders for construction or repairs, conducting standardized and custom testing of parts throughout their lifespan, and identifying failure modes while verifying material properties at end of life.

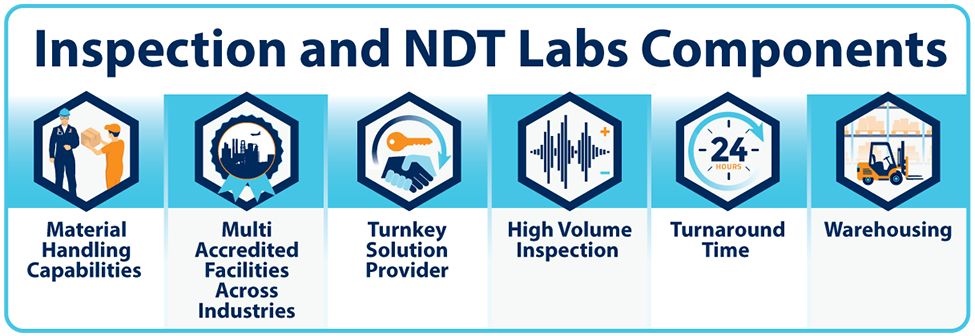

Efficient, Cost-Effective Lab Services

Acuren is the North American industry leader in laboratory nondestructive testing and inspection services. Acuren’s laboratory services are designed to reduce overhead, labor and overall testing and inspection costs. With our focus solely on customer needs Acuren can increase lab efficiency allowing our customer to reduce overall product turn time. This is achieved through a highly trained technical staff utilizing the proper equipment.

Dependable and affordable inspection services

Acuren provides a comprehensive range of traditional and advanced NDT/NDE methods for precise, cost-effective inspections, supported by rigorous safety, training, and quality programs to ensure consistent, repeatable results.

- Training, Level III & Consulting Services

- In-Lab NDT Services

Training, Level III & Consulting Services

Acuren maintains comprehensive training programs to support our customers inspection needs. All courses are designed to comply with SNT-TC-1A guidelines. In addition to our training programs, Acuren provides Level III and Consulting Services to assist our customers in meeting their inspection goals.

|

|

In-Lab Nondestructive Testing Services

|

|

Certifications

Matheson Tri-Gas

Bell Helicopter

Electric Boat

FMC

GE Aerospace

GE Oil/Gas

Honeywell

Intermountain Electronics

ITAR

Lockheed Martin

Lycoming

Murphy Company

Northrop Grumman

Parker Hanifin

Pratt & Whitney

Product Control Services

Rolls Royce

Safran

Sikorsky

SpaceX

Spendrup

Sundstrand

Excellence in Quality Assurance

Specializing in high-volume applications, we offer fast, hassle-free services with clear, concise reporting, empowering clients to make informed decisions. Our extensive experience, network of facilities, and investment in cutting-edge technologies allow us to meet the most demanding inspection and QA needs. Acuren holds certifications across virtually all industries, ensuring top-quality results every time.

Why Choose Acuren

Specialized Testing Centers

Designated centers of expertise for specialized testing and quick specimen preparation via in-house machine shops.

NADCAP, NAS-410 & ISO 17025 Accredited

NADCAP, NAS-410 and ISO 17025 accredited across various locations for mechanical, chemical, and nondestructive testing.

Expert Network Advantage

Extensive network of experts and facilities eliminates the need for outsourcing, ensuring high-volume capability.

Consistent Service Excellence

Consistency in services and accreditations across locations, supporting shipping logistics and warehousing needs.

Expert Laboratory Services From The Industry Leader

Acuren is the North American industry leader in laboratory nondestructive testing and inspection services. We provide expert services and tailored inspection plans to help other industry leaders meet their quality and inspection needs.

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Industry Training

Acuren offers specialized training in Nondestructive Testing (NDT), API certification, pipeline codes, and rope access, blending practical and theoretical instruction tailored to industry demands. With experienced instructors, hands-on practice, and on-site or online options, Acuren’s programs equip professionals with essential skills and certifications.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →