Guided Wave Services

Reduce Maintenance, Increase Safety and Optimize Your Process

Capable of detecting internal or external defects, Guided Wave is an advanced NDE technique providing rapid screening of an in-service pipeline. Long range inspection can be achieved from a single location as ultrasonic guided waves travel in both directions along the pipe, remotely scanning difficult to access areas in a single pass.

This innovative inspection technique reduces costs through minimal insulation removal, limited scaffolding and excavation, and shortened deployment times. Couplant is not used for this procedure and follow-up inspection for exact sizing and characterization is required to target problematic areas. Whether inspecting small or large pipes, our experienced technicians use qualified procedures and sophisticated analysis in identifying and reporting results.

Guided wave can reduce inspection preparation costs by:

- Reducing pipeline excavations

- Enabling inspection of piping under roads and cased crossings

- Extensive insulation removal is not required

- Only a single point of access required to rack piping

- Minimal removal of external coating

Advanced NDE Provides Rapid Screening of In-Service Pipeline

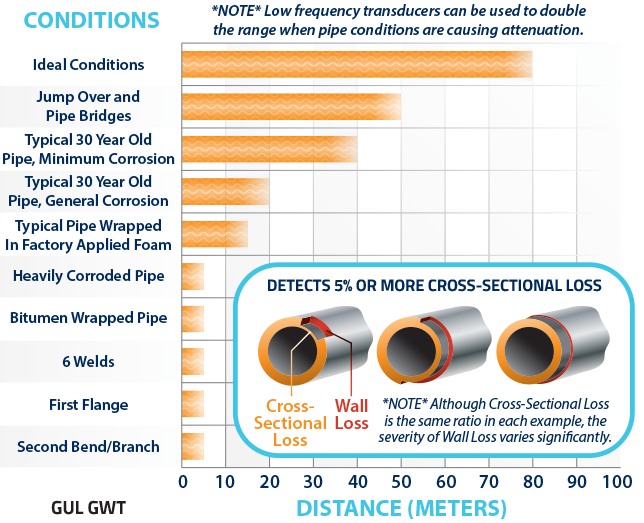

A defect which reduces the pipe cross-sectional area by 5% or more can be detected, in a guided wave scan, and scan data is obtained dramatically faster than localized inspection methods. Our technicians strictly adhere to manufacturer training and comprehensive internal training programs.

A defect which reduces the pipe cross-sectional area by 5% or more can be detected, in a guided wave scan, and scan data is obtained dramatically faster than localized inspection methods. Our technicians strictly adhere to manufacturer training and comprehensive internal training programs.

The result is a classification of wall loss (mild – less than 25%, medium – 25 to 50%, severe – greater than 50%) and an estimate of the percentage of wall loss. To get exact values we recommend follow-up with regular UT or RT.

Some generalizations about distance are illustrated in this table:

Typical guided wave applications include:

- Petrochemical plant pipework

- Risers

- Road crossings

- Bridge piers

- Poorly accessible pipework

Our advanced services team would be happy to discuss your needs and determine the right technology for your application.