- About

- About Overview

- Vision & Values

- Leadership Teams

- Corporate

- Canadian Operations

- United States Operations

- Service Line

- Safety

- Quality

- Environment

- Sustainability

- Indigenous Policy

- Hellier Training

- Applied Inspection

- Engineering

- Engineering Overview

- Field Engineering

- Field Engineering Overview

- Ferrite Testing

- Hardness Testing

- Metallurgical Replicas

- Optical Emission Spectroscopy (OES)

- Positive Material Identification (PMI)

- Materials Testing & Analysis

- Materials Engineering

- Metallurgical Condition Assessment

- Steam Cycle Chemistry Services

- STRAP – Steam Turbine Risk Assessment Program

- Support for Industrial Insurers and Independent Adjusters

- Water Treatment Technologies Services

- Reliability Engineering

- Vibration Analysis

- Inspection

- Inspection Overview

- Advanced NDE/NDT

- Moisture Detection Imaging (MDI)

- Non-Intrusive/On Stream Inspection Program

- Phased Array Services

- Time of Flight Diffraction Technique (ToFD)

- Tube to Tube Sheet Weld Inspection

- NDE/NDT

- Visual Inspection (VT)

- National Board Program

- Drone & Robotic Inspection Services

- Lab Services – Inspection & NDT

- Rope Access for Inspection

- Inspection Training

- Rope Access Industrial Services

- Solutions

- Access Planner

- Ammonia Systems Inspection Services

- Asset Integrity Management / Mechanical Integrity

- Cathodic Protection Services

- Corrosion Under Insulation

- Drone & Robotic Inspection Services

- Facilities Piping Management Programs

- High Energy Piping Programs & Solutions

- Hydrogen Industry

- Laboratory Services – Inspection and NDT

- Laboratory Services – Materials Testing & Analysis

- Midstream Integrated Integrity Solutions

- National Board Program

- Non-Intrusive/On Stream Inspection Program

- PHMSA Mega Rule Solutions

- Research and Application Development

- Rope Access for CUPS

- Industries

- Industries Overview

- Aerospace

- Automobile

- Building & Infrastructure

- Chemical

- Food and Beverage

- Insurance & Litigation

- Manufacturing

- Metal Fabrication

- Mining

- Nuclear Power

- Oil & Gas

- Pipeline

- Pipeline Integrity Engineering Services

- Pipeline Integrity Field Services

- Power Generation

- Pulp & Paper

- Rail

- Tanks

- Wind

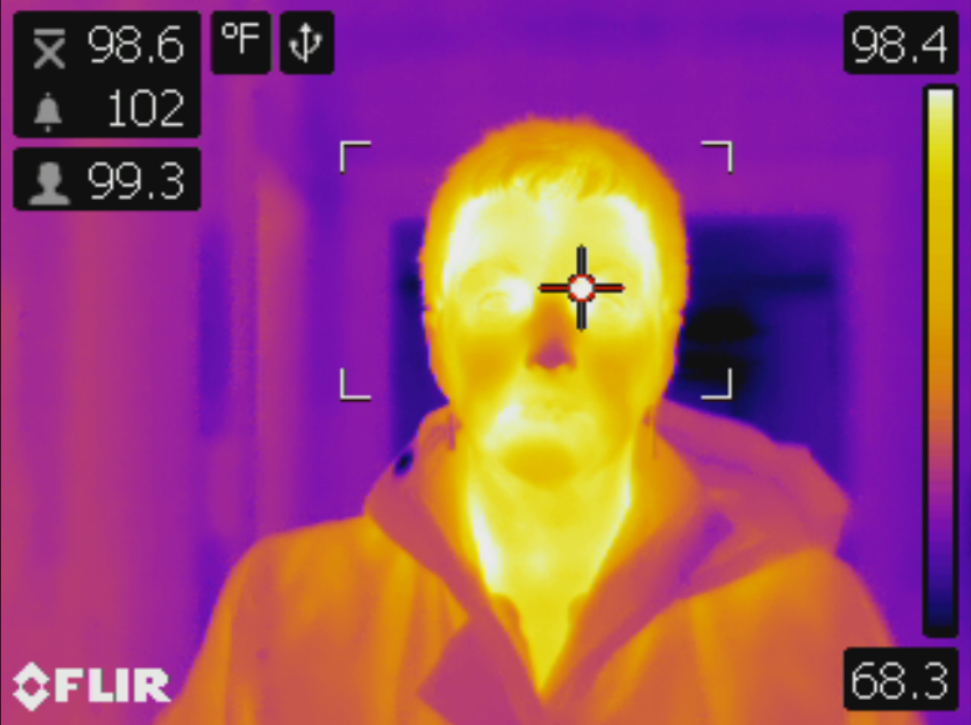

- Safety – Scans are completed from outside the social distancing zone as opposed to traditional test methods

- Approved Process – This proven practice has been previously utilized within industry for identifying elevated body temperatures. Acuren has an approved QMS procedure for body temperature determination.

- Certifications – Calibrated and certified equipment operated only by trained technicians/engineers

- Accuracy – This technology offers a high degree of accuracy, ± 0.1°C

- Visibility of subject’s tear duct area

- Small indoor space on customer site, free of encumbrances with power supply (space must accommodate regulated social distancing guidelines)

- 10-15 seconds required to record each temperature

- Tolerance temperature determined by customer

- Customer representative onsite reviews every scan in real time to make a decision on each employee’s access to site

- No scans conducted without presence of client representative

- Acuren does not retain any personal information, video or images

Infrared Monitoring of Body TemperatureJuly 10, 2020

Thermal imaging using infrared thermography equipment is an effective non-contact solution for detecting small temperature changes in the human body. By providing a temperature reading this technology will assist a client in making a recommended action.

Our technicians and engineers can assist you in making immediate decisions around granting access to your site.

SIMPLE REQUIREMENTS

Scan body temperature quickly and accurately while maintaining social distance

Scan body temperature quickly and accurately while maintaining social distancePlease speak with our team of specialists to learn more and understand how we can help you navigate these most challenging times on your site.

reliabilityservices@acuren.com

1-800-252-1774Our ServicesEngineeringAcuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.InspectionAcuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.Rope Access Industrial ServicesAcuren provides integrated industrial services including inspection, repair and maintenance via rope access using composite crews with multi-disciplined trades, experienced personnel, IRATA certified technicians, and customized access optimization programs.Success StoriesMonthly Maintenance Contract Pays DividendsEach month Acuren Condition Based Monitoring Specialists collect machinery vibration and structure borne ultrasonic data as part of the regular condition monitoring program at Irving Wallboard.

Ropes Team Saves Thousands on Pump Box WorkDuring a planned outage ultrasonic testing and visual inspection revealed that a significant portion of the pump box floor either needed to be repaired, or cut out and replaced.

Related IndustriesAerospaceAcuren has a specialized team with aerospace industry experience that use both traditional and advanced nondestructive testing methods to identify defects in critical structural, airframe, and engine and accessory components.MiningAcuren’s engineering, inspection and industrial services teams consist of engineers, technologists and tradespeople with a diverse educational background, working in the mining industry for over 40 years.RailWe are familiar with the unique codes and regulations of the rail industry, including DOT in the US and Transport Canada, and we're constantly innovating to create enhanced testing procedures that ensure optimum quality and safety.