- About

- Engineering

- Engineering Overview

- Field Engineering

- Field Engineering Overview

- Ferrite Testing

- Hardness Testing

- Metallurgical Replicas

- Optical Emission Spectroscopy (OES)

- Positive Material Identification (PMI)

- Materials Testing & Analysis

- Laboratory Services – Materials Testing & Analysis

- Sour Gas Corrosion Testing

- Materials Engineering

- Metallurgical Condition Assessment

- Steam Cycle Chemistry Services

- STRAP – Steam Turbine Risk Assessment Program

- Support for Industrial Insurers and Independent Adjusters

- Water Treatment Technologies Services

- Reliability Engineering

- Vibration Analysis

- Inspection

- Inspection Overview

- Advanced NDE/NDT

- Moisture Detection Imaging (MDI)

- Non-Intrusive/On Stream Inspection Program

- Phased Array Services

- Time of Flight Diffraction Technique (ToFD)

- NDE/NDT

- Visual Inspection (VT)

- National Board Program

- Drone & Robotic Inspection Services

- Inspection Training

- Rope Access Industrial Services

- Solutions

- Access Planner

- Ammonia Systems Inspection Services

- Asset Integrity Management / Mechanical Integrity

- Cathodic Protection Services

- Corrosion Under Insulation

- Drone & Robotic Inspection Services

- Facilities Piping Management Programs

- High Energy Piping Programs & Solutions

- Hydrogen Industry

- Laboratory Services – Materials Testing & Analysis

- Midstream Integrated Integrity Solutions

- National Board Program

- Non-Intrusive/On Stream Inspection Program

- PHMSA Mega Rule Solutions

- Research and Application Development

- Rope Access for CUPS

- Industries

- Industries Overview

- Aerospace

- Automobile

- Building & Infrastructure

- Chemical

- Food and Beverage

- Insurance & Litigation

- Manufacturing

- Metal Fabrication

- Mining

- Nuclear Power

- Oil & Gas

- Pipeline

- Pipeline Integrity Engineering Services

- Pipeline Integrity Field Services

- Power Generation

- Pulp & Paper

- Tanks

- Wind

Home NewsNews

April 19, 2024Strategic Acquisition of Advance Coating Solutions Inc.

April 19, 2024Strategic Acquisition of Advance Coating Solutions Inc.We are pleased to announce that Acuren Group Inc. has acquired Advance Coating Solutions Inc., a leading provider of coatings and blasting solutions in Western Canada. The acquisition closed Monday April 15, 2024. This acquisition will enhance Acuren’s Rope Access Technician Solutions by delivering turnkey corrosion prevention and remediation solutions to our customers, across a […]

April 3, 2024Welcome, ADV Integrity

April 3, 2024Welcome, ADV IntegrityWe are pleased to announce that Acuren has acquired ADV Integrity, a leading provider of engineering, materials testing and analysis, and technology development. The acquisition closed April 2, 2024. This acquisition will enhance Acuren’s service offering by delivering turnkey comprehensive integrity management solutions to our customers, particularly across the Midstream and Pipeline Integrity markets. This […]

September 14, 2023Acuren Acquires Alloyweld Inspection

September 14, 2023Acuren Acquires Alloyweld InspectionAcuren, the industry leader in nondestructive testing (NDT), inspection, engineering, and rope access integrated services, has acquired Alloyweld Inspection. This acquisition brings Alloyweld’s 55-years of nondestructive testing experience and team of experts into the Acuren family of companies and broadens the range of services available to customers of both companies. Located in Bensenville and Elgin, […]

January 9, 2023Proud to Employ the Best

January 9, 2023Proud to Employ the BestAcuren is pleased to celebrate Keeley Prockiw, who will receive Queen Elizabeth II’s Platinum Jubilee medal in Alberta, Canada this month. Prockiw, a RAIS Planner/Coordinator for Tacten, an Acuren company, was nominated for this prestigious award based on her outstanding contributions to Albertans. She is a steadfast advocate for women and underrepresented genders in trades, […]

March 30, 2022Acuren Acquires Cambridge Materials Testing

March 30, 2022Acuren Acquires Cambridge Materials TestingAcuren, the industry leader in nondestructive testing (NDT), inspection, engineering, and rope access integrated services, has acquired Cambridge Materials Testing Limited. The acquisition expands the breadth and depth of Acuren’s lab testing capabilities, particularly in the aerospace, nuclear, medical, and consumer end markets, while providing Cambridge customers a broader range of services, such as non-destructive […]

November 19, 2021Acuren Acquires Premium Inspection & Testing Group

November 19, 2021Acuren Acquires Premium Inspection & Testing GroupAcuren, the industry leader in nondestructive testing (NDT), inspection, engineering, and rope access integrated services, has acquired Premium Inspection and Testing Group. Acuren plans to retain all employees and leadership teams to continue growing both companies and provide customers a broader range of service capabilities. Headquartered in Baton Rouge, Louisiana, Premium Inspection offers conventional and […]

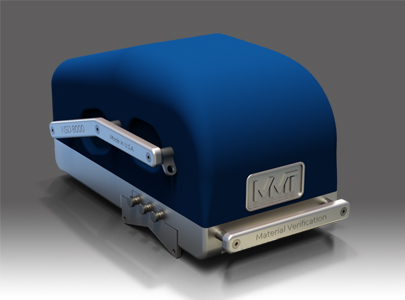

September 7, 2021Purchase of MMT’s HSD Testers Underscores Acuren’s Commitment to Mega Rule Material Verification Needs of Pipeline Operators

September 7, 2021Purchase of MMT’s HSD Testers Underscores Acuren’s Commitment to Mega Rule Material Verification Needs of Pipeline OperatorsAcuren Deploys HSD Testers to Improve Pipeline Safety and PHMSA Compliance Initiatives Among Gas Transmission Operators As part of Acuren’s material verification solutions geared towards PHMSA Mega Rule compliance, Acuren purchased four HSD 8000 Tester units from MMT to support the operational safety and Mega Rule compliance needs of Local Distribution Company (LDC) customers. Along […]

November 6, 2020Acuren Acquires Complete Wind Corporation

November 6, 2020Acuren Acquires Complete Wind CorporationWe are pleased to announce Acuren has acquired Complete Wind Corporation (CWC). CWC offers dynamic balancing, rotor blade inspection, repair, engineering and quality assurance services to wind farm owner and operators in Canada and the United States. Acquiring CWC will strengthen our wind turbine inspection and repair capabilities and complement our June 2020 Suspendem acquisition, […]

June 17, 2020Acuren Acquires Suspendem

June 17, 2020Acuren Acquires SuspendemDelivering a ‘Higher Level of Reliability’ to the Wind Energy Industry Edmonton, AB, June 15, 2020 – Acuren Inc., the global provider of nondestructive testing, inspection, engineering and rope access integrated services, announces the acquisition of Suspendem, a leading provider of wind turbine maintenance and inspection services in North America. The acquisition combines Acuren’s substantial […]

September 26, 2019An Introduction to Coal Silo Failures

September 26, 2019An Introduction to Coal Silo FailuresSummary Over the past few years, there have been several coal silo failures in power plants in the US and abroad. These failures have dropped as much as 800 tons of coal on the floor below them. To date no injuries have occurred but significant equipment damage has resulted. The most common cause of failure […]