What is Sour Gas Corrosion Testing?

The exposure of some metallic components to sour (i.e. H2S containing) aqueous environments can potentially lead to corrosion and/or environmentally assisted cracking. Environmentally assisted cracking comprises several specific cracking mechanisms such as sulfide stress cracking (SSC), stress corrosion cracking (SCC) and hydrogen induced cracking (HIC), among others.

All of these cracking mechanisms require a susceptible material, in either a stress or unstressed state, in an aqueous sour environment. NACE (now known as AMPP) has developed several standard test methods that define and create a sour gas containing corrosive environment and standard loading conditions that can be used to help assess a materials’ relative resistance to these various forms of environmentally assisted cracking.

Why Sour Gas Corrosion Testing?

By conducting tests according to these standards, users can ensure the reliability, safety, and longevity of their infrastructure and equipment, ultimately reducing the risk of costly failures, environmental damage, and ensuring the safety of personnel.

Contact Acuren

Why Acuren?

The various sour gas corrosion testing procedures described by NACE require very strict control of all testing variables. At Acuren, we prioritize protection of your infrastructure, offering comprehensive solutions to address potential risks associated with sour gas to ensure the longevity of your assets. We recognize the urgent need to assess material properties and our experts proactively identify and mitigate the potential risks when materials are exposed to sour fluids, providing you with peace of mind and reliable asset longevity.

Experience

With over 40 years of experience in this field, our team has developed procedures to ensure that we consistently and repeatedly meet all of these requirements.

In-house machining

All our test specimens are machined in-house to ensure consistent fabrication within all specified tolerances and the fastest possible turnaround time to meet our client’s needs.

Quality

Our sour gas corrosion testing lab is supported by a network of ISO 17025 accredited labs that can provide other materials testing options (e.g. tensile testing, impact testing, fracture mechanics testing, chemical analysis, etc.) and a deep bench of experienced materials engineers who can help with any of your material issues/failures.

Engineering expertise

Acuren has the largest network of laboratories across North America with specialized engineers who can examine your components for potential damage, perform failure analysis and materials selection to ensure optimal asset reliability.

Types Of Sour Gas Corrosion Tests We Perform

NACE TM0177 – Testing of Metals for Resistance to Sulfide Stress Cracking (SSC) and Stress Corrosion Cracking (SCC) in H2S Environments

This test standard provides guidance to assess a material’s resistance to cracking failure under the combined action of applied stress and corrosion in aqueous environments containing hydrogen sulfide (H2S). Several methods of applying stress and assessing performance are provided within NACE TM0177. All require immersion of the test specimen in a low pH, aqueous sour (i.e. H2S containing) environment for a prolonged period of time. Standard test conditions (including 4 standard test solutions) are defined in NACE TM0177 but, custom test conditions can be created to suit your needs.

Method A: Tensile Test

A simple, unnotched test specimen is loaded in static uniaxial tension (via proof ring) and placed in the environmental test vessel for up 720 hours. The absence of specimen fracture/cracking is acceptable, while cracking or fracture constitutes a failure. By testing a material at different stress levels, an apparent threshold stress level can be determined below which cracking due to SSC would not be expected.

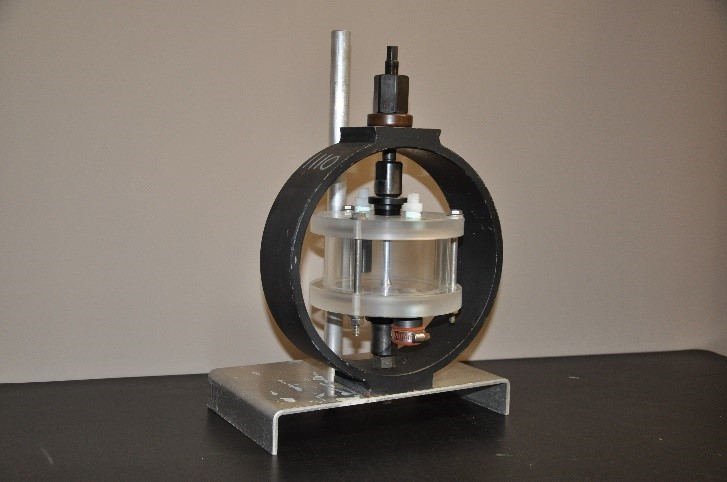

Method C: C-Ring Test

A “C” shaped partial ring of material (typically from a tubular type product) is loaded circumferentially and placed in the environmental test vessel for up to 720 hours. The absence of specimen fracture/cracking is acceptable, while cracking or fracture constitutes a failure. By testing a material at different stress levels, an apparent threshold stress level can be determined below which cracking due to SSC would not be expected.

Method D Double Cantilever Beam (DCB) Test

Unlike Method A or Method C (which are typically fail/no-fail) the double cantilever beam or DCB test described in Method D gives a measurement of a material’s resistance to propagation of environmentally assisted cracking expressed in the form of a critical stress intensity factor, KISSC for the applied test/environmental conditions. The DCB specimen is loaded by inserting a wedge between the two arms to create a static load at the crack starter (notch or EDM) before being placed in the environmental test vessel. For a test to be valid, some cracking must be present after the exposure time (typically 14 days). To ensure that cracking occurs in some lower strength materials, fatigue pre-cracking prior to exposure to the sour environment may be required.

NACE TM0284 – Evaluation of Pipeline & Pressure Vessel Steels for Resistance to Hydrogen-Induced Cracking

The corrosion of steel in wet, sour (i.e. H2S containing) environments leads to the generation of atomic hydrogen that can be absorbed by the steel. This can lead to adverse effects on the material such as blistering and cracking in a mechanism broadly characterized as hydrogen induced cracking (HIC). HIC is known that to have caused significant failure events in pipelines and pressure vessels in sour service conditions.

NACE TM0284 provides guidance for testing of specimens from pipes, plates, fittings and flanges. The samples are tested in an unstressed condition in one of 3 standard test solutions. For Solutions A and B, the standard exposure period is 96 hours (4 days). For Solution C, the test duration is a function of the H2S partial pressure used and can range from 96 hours (4 days) to 2160 hours (90 days). Custom test conditions can be designed to suit your needs.

After exposure, the samples are visually examined (looking for blistering, etc.) and metallographic cross-sections are prepared to look for evidence of cracking. Any cracks present are measured to determine the crack sensitivity ratio (CSR), crack length ratio (CLR) and crack thickness ratio (CTR).

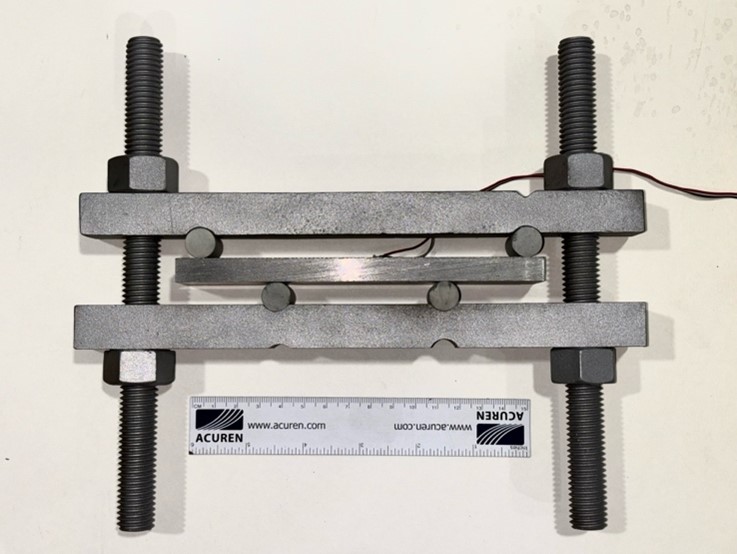

NACE TM0316 Four-Point Bend Testing of Materials for Oil and Gas Applications

NACE TM0316 describes the use of four-point bend testing to evaluate the resistance of metals, including carbon steels, low alloy steels, and corrosion resistant alloys (CRAs), to stress corrosion cracking (SCC) and sulfide stress cracking (SSC). Welded or clad materials can also be tested so that the base material, heat affected zone (HAZ) and weld/cladding materials are also assessed. The material tested is placed in a compact four-point bending jig so that the face of the specimen is stressed in tension and the reverse face is loaded in compression. The test is conducted at a specific tensile stress load that may be measured by deflection or strain gauge methods. The loaded specimens are then placed in the environmental test vessel containing one of the 4 standard test solutions (A, B, C, or D) as defined in NACE TM0177 or in custom test solutions to suit your needs. Upon completion of exposure, the test specimens are examined to look for any evidence of cracking.

Do you fabricate, design, supply, or operate infrastructure in a sour service environment?

If yes, Acuren can test your materials to the following industry standards NACE TM0177, NACE TM0284, NACE TM0284, NACE TM0316. These tests are important to help ensure safe operation of downhole products, pipelines, and storage vessels, and for identifying suitable materials for use in sour, corrosive environments.

Evan Wan

Operations Manager, Sour Gas Corrosion Testing Prairies Region

T 403.250.7081

C 403.608.7915

E evan.wan@acuren.com

2157 23 Street NE, Calgary, AB, T2E 8J8, CANADA