- About

- Engineering

- Engineering Overview

- Field Engineering

- Field Engineering Overview

- Ferrite Testing

- Hardness Testing

- Metallurgical Replicas

- Optical Emission Spectroscopy (OES)

- Positive Material Identification (PMI)

- Materials Testing & Analysis

- Laboratory Services – Materials Testing & Analysis

- Sour Gas Corrosion Testing

- Materials Engineering

- Metallurgical Condition Assessment

- Steam Cycle Chemistry Services

- STRAP – Steam Turbine Risk Assessment Program

- Support for Industrial Insurers and Independent Adjusters

- Water Treatment Technologies Services

- Reliability Engineering

- Vibration Analysis

- Inspection

- Inspection Overview

- Advanced NDE/NDT

- Moisture Detection Imaging (MDI)

- Non-Intrusive/On Stream Inspection Program

- Phased Array Services

- Time of Flight Diffraction Technique (ToFD)

- NDE/NDT

- Visual Inspection (VT)

- National Board Program

- Drone & Robotic Inspection Services

- Inspection Training

- Rope Access Industrial Services

- Solutions

- Access Planner

- Ammonia Systems Inspection Services

- Asset Integrity Management / Mechanical Integrity

- Cathodic Protection Services

- Corrosion Under Insulation

- Drone & Robotic Inspection Services

- Facilities Piping Management Programs

- High Energy Piping Programs & Solutions

- Hydrogen Industry

- Laboratory Services – Materials Testing & Analysis

- Midstream Integrated Integrity Solutions

- National Board Program

- Non-Intrusive/On Stream Inspection Program

- PHMSA Mega Rule Solutions

- Research and Application Development

- Rope Access for CUPS

- Industries

- Industries Overview

- Aerospace

- Automobile

- Building & Infrastructure

- Chemical

- Food and Beverage

- Insurance & Litigation

- Manufacturing

- Metal Fabrication

- Mining

- Nuclear Power

- Oil & Gas

- Pipeline

- Pipeline Integrity Engineering Services

- Pipeline Integrity Field Services

- Power Generation

- Pulp & Paper

- Tanks

- Wind

Home Success Stories Acuren’s Experts Complete Project at Extraordinary Run RateAcuren’s Experts Complete Project at Extraordinary Run Rate

Acuren’s Raleigh, North Carolina team just safely completed a project in less than four days which consisted of 250,000 conventional ultrasonic testing readings for a power industry client. The project was swiftly executed thanks to our experts strategically planning the major outage inspection as part of a shutdown.

Acuren’s Raleigh, North Carolina team just safely completed a project in less than four days which consisted of 250,000 conventional ultrasonic testing readings for a power industry client. The project was swiftly executed thanks to our experts strategically planning the major outage inspection as part of a shutdown.The project was completed in seven shift rotations averaging over 31K UT readings per shift. The properly staffed team was composed of 33 technicians. The techs were organized into two, three-person layout crews per shift working to layout elevations in front of the UT readers.

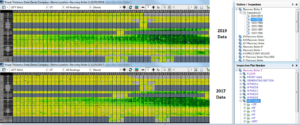

The UT readings were taken in conjunction with our BEAM software. Acuren’s Boiler Exam and Analysis Management Software (BEAM) is a new generation of boiler inspection application, developed in-house, using the latest software development technologies, graphical capabilities and database programs. BEAM has trending capabilities so it calculates multiple data points to project when it will fall below minimum allowable thicknesses which facilitates planning said replacements and minimizing the risk of forced outages. BEAM clients can securely access their reports through BEAM online services reports 24 / 7 / 365 in a mission critical data center.

Acuren’s project planning and software development illustrate continued commitment to providing the market with leading inspection services.

If you need support implementing a timely inspection project reach out to Acuren today at 1-800-218-7450 or email us.