Home › Wind Turbine Blade & Main Shaft Inspection Applications

Wind Turbine Blade & Main Shaft Inspection Applications

Wind Turbine Blade and Main Shaft Inspection Applications

- Wind Turbine Blade Root Inspection

- Wind Turbine Blade Spar Cap Inspection

- Main Shaft Inspection

Wind Turbine Blade Root Inspection

- Inspection target: detection of de-laminations/dis-bonds in turbine blade’s root section (Glass Fiber Reinforced Polymer, GFRP)

- Inspection technique developed based on using low frequency conventional and phased array probes & Real turbine blade root section cut out used as calibration piece

- Bolt holes and made calibration targets were detected; Backwall trace showed sound penetration up to 4” from the surface

- Integrated in Acuren Turbine Blade Inspection program

Deployment: Wind Turbine Blade Root Inspection

- Blade Root Sections inspected on site and areas with delamination were market on the blade

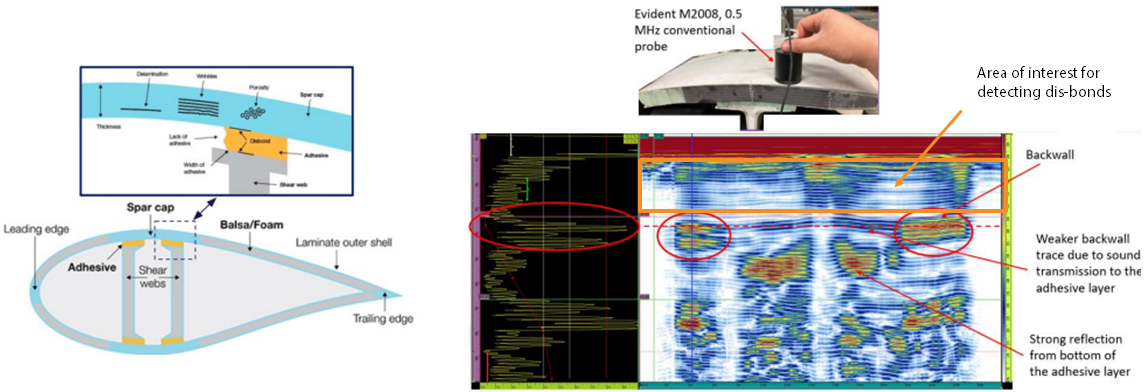

Wind Turbine Blade Spar Cap Inspection

- Inspection target: detection of de-laminations/disbands in turbine blade’s Spar section (Glass Fiber Reinforced Polymer, GFRP and Carbon Reinforced Polymer, CFRP) and adhesive bond

- Inspection technique developed based on using low frequency conventional and phased array probes & Real turbine Spar section cut out used as calibration piece

Deployment: Wind Turbine Blade Spar Cap Inspection

- Technique demonstrated detection of dis-bond in both spar cap region and adhesive layer

- Inspection technique Integrated in Acuren Turbine Blade Inspection program

Wind Turbine Main Shaft Inspection

- Technique detecting cracks in main shaft of wind turbines developed for client

- Several shafts tested, one identified as potentially cracked

- More sophisticated, high resolution technique proposed for verification and through wall sizing

- New technique tested on demo sample cracked all the way through, crack facets clearly imaged

- Broader deployment with high resolution technique to be performed in 2024

Highlights of Projects

Phase Coherence Imaging (PCI) Based Applications

Application Based On Auto Highlighting Scan Data Anomalies

Phased Array Based Inspection Applications

FMC/TFM Based Inspection Applications

Software Based Inspection Solutions

Contact our experts today!

Contact Acuren