Software Based Inspection Solutions

- BeamTool 10: FMC/TFM Technique Design Tools

- Assisted Analysis Software: Platform for UT Data Analysis

Software: Advanced FMC/TFM Technique Design Tools

- Added functionality to Eclipse Scientific’s BeamTool software to optimize FMC/TFM based technique design

- Fast simulation of TFM image of small “point” target throughout imaging domain – so called Point Spread Function (PSF)

- Size, shape and amplitude of PSF mapped throughout chosen imaging region, quantify how well focused TFM image will be

- Helps to estimate expected sizing accuracy of technique

Software: Assisted Analysis Platform

- Software Platform to leverage developed post processing algorithms (ex. Shannon information processing) for custom and standard inspection applications

- Minimizes operator’s errors (missing indications, false calls) specifically for inspections with challenging geometries

- Decrease analysis time ideal for general Weld Inspection for large inspection campaigns

Assisted Analysis Platform – General Weld Inspection

- Software for semi-automated analysis of ultrasonic data

- Corrected to geometry views (folding) with correct overlay imported from BeamTool

- Excluding data outside of regions of interested (weld volume & HAZ)

Assisted Analysis Platform – General Weld Inspection

- Common codes (ASME, ISO, AWS) algorithmically for detection and sizing, acceptance criteria automatically applied, defect table generated by software

- Analyst reviews software generated defect table, remove false calls and geometric indications

- Reports auto-generated

- Merged projection views, polygon image gating and beam folding for complex geometries supported

- Anomaly detection (Shannon Information) view implemented, limit false calls

- Up to 5 x time savings in analyzing scan files

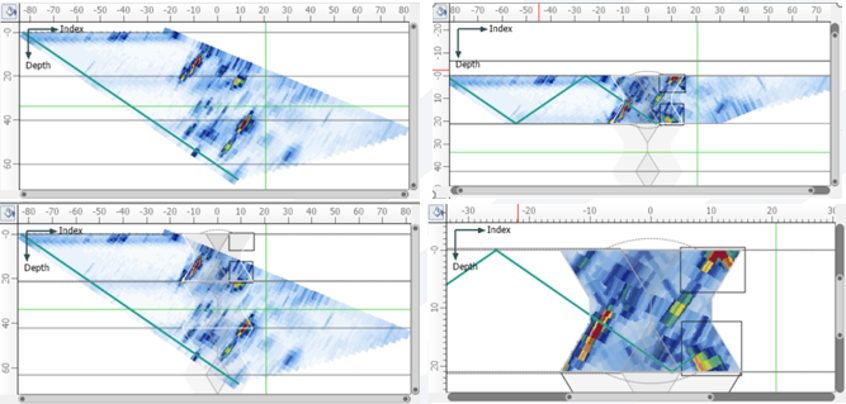

Assisted Analysis Platform – Beam Folding for Inspection in Axial Direction

- True to geometry folding facilitates analysis for characterization and sizing

- Provides major advantage for seam weld/ERW weld inspection

- Removes imprecision in positioning flaws through wall on axial pieces

Highlights of Projects

Phase Coherence Imaging (PCI) Based Applications

Application Based On Auto Highlighting Scan Data Anomalies

Phased Array Based Inspection Applications

Wind Turbine Blade & Main Shaft Inspection Applications

FMC/TFM Based Inspection Applications

Contact our experts today!

Contact Acuren