Tank Inspection and Maintenance

Acuren has the equipment and certified professionals ready to efficiently carry out comprehensive API and non-API tank inspections, including those governed by API 653 standards. We inspect tanks of any material or size—large diameter, small diameter, vertical, or horizontal—with precision and reliability.

Our Experience

in Numbers

Full-Service Storage Tank Inspection and Maintenance

Our inspection programs include internal and external evaluations, corrosion analysis, and laser scanning, using techniques aligned with API 653 to ensure regulatory compliance and operational safety. Acuren also offers Fitness-For-Service assessments, helping clients extend tank life while minimizing downtime and unnecessary repairs.

- Laser Scanning

- Fitness for Service

- Rope Access

Laser scanning provides a fast, accurate, and cost-efficient approach to API 653 tank inspections.

Laser scanning captures millions of data points in a single scan, allowing inspectors to quickly and accurately assess settlement, deformation, and perform volumetric calibration (strapping).

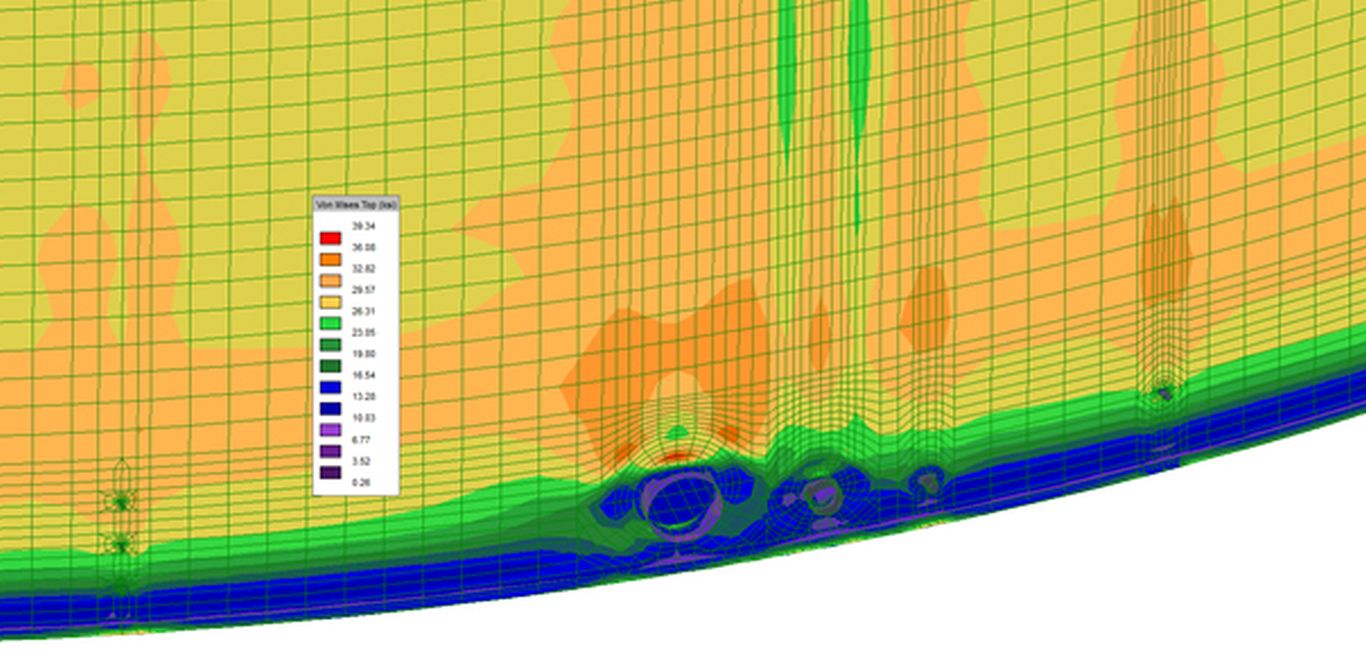

This technology produces high-resolution visuals and a permanent 3D model of the tank’s current condition—providing a valuable baseline for future inspections. The data is verifiable, repeatable, and can be exported to tools like Excel, AutoCAD, and SolidWorks. It also supports advanced engineering analysis such as Finite Element Analysis (FEA).

The result: faster inspections, better data, fewer shutdowns, and smarter long-term maintenance decisions.

Start Your Inspection Today

Ensure Compliance and Avoid Downtime with API-Based Fitness-for-Service Assessments

Acuren offers comprehensive Fitness-for-Service (FFS) assessments for storage tanks, adhering to API 579-1 / ASME FFS-1 standards. These evaluations determine whether a tank with existing flaws or damage can continue safe operation, potentially eliminating the need for hydrostatic testing after major repairs. By employing advanced techniques like finite element analysis and rigorous stress evaluations, Acuren ensures compliance with API 653 requirements, helping clients avoid unnecessary downtime and reduce costs. In one instance, Acuren's FFS methodology saved a client over $100,000 and 30 days by exempting a large crude storage tank from hydrostatic testing.

Speak to our Experts

Safe, Efficient Rope Access Solutions for Storage Tank Work

Acuren’s certified rope access technicians provide a safer, faster, and more cost-effective alternative to traditional scaffolding for storage tank inspections, maintenance, and repairs. By eliminating the need for complex access structures, we minimize downtime and deliver critical services—such as API 653 inspections, cleaning, and NDE—quickly and with minimal disruption to operations.

Work with us

End-to-End Capabilities for Storage Tank Integrity

Acuren delivers cost-effective tank inspection solutions backed by extensive industry experience. Our proven approach allows us to offer condition-based fixed pricing, ensuring transparency and value. We understand the critical role storage tanks play in your operations, and we’re committed to completing essential inspection tasks efficiently—regardless of your tank’s condition.

- API series tanks with fixed or floating roofs

- STI/SPFA shop-built or field erected tanks

- AWWA water storage tanks

- Fiberglass reinforced plastic tanks

- NFPA water-based fire protection storage tanks

- External inspections

- Ultrasonic thickness inspections

- Ultrasonic crawlers

- Internal inspections

- Magnetic Flux Leakage (MFL) scanning

- Alternating Current Field Measurement (ACFM)

- Eddy Current Testing (ET)

- In-service inspections

- Out-of-service inspections

- Certified welding inspections

- Post repair inspections

- Risk-based inspections

- Settlement surveys

- Roundness surveys

- Vacuum box leak testing

- Traditional nondestructive examinations

- Short range guided wave inspection

- Long range laser scanning

- Infrared scanning

- Alternating Current Field Measurement (ACFM)

- Eddy Current Testing (ET)

- Phased Array Ultrasonic Testing (PAUT)

- Phased array in lieu of radiography

- Time of Flight Diffraction (TOFD)

- Hardness testing

- Positive Material Identification (PMI)

- Optical Emission Spectrometry (OES)

- In-site metallography

- Laboratory failure analysis

- Aerial drones

3D Laser Measurement of Tank Shell Deformations

- Tank program development

- API 579-1 / ASME FFS-1 fitness for service assessments

- Hydrostatic test exemptions

- Rigorous stress analysis

- Finite element analysis

- Tank repair plan

- Field service engineering

- Construction management

- Inspections

- NDE

- Welding

- Insulation

- API 510 pressure vessel inspections

- API 570 in-service piping inspections

- NACE coating inspections

- NACE corrosion inspections

- Job hazard analysis

- Safe work plans

- OSHA training

- Operator Qualification (OQ)

- TWIC card

Finite Element Analysis Saves Client $500K and 60 Days

When a client faced significant bottom settlement in an aviation fuel tank—exceeding API 653 limits—they anticipated a costly and time-consuming repair process, estimated at two months and approximately $500,000. Acuren proposed an alternative: employing Finite Element Analysis (FEA) to assess the tank's structural integrity. By creating a detailed FEA model with over 26,000 elements, Acuren demonstrated that the tank's stresses remained within allowable limits, eliminating the need for repairs. This approach reduced the project's duration to one week and costs to under $20,000, saving the client over $500,000 and 60 days of downtime.

Partner With Acuren for Storage Tank Maintenance & Inspections

If you are looking for a reliable water tower inspection and maintenance company, choose Acuren for all your storage tank needs. Our integrated programs help set clients up for longterm success to avoid critical asset failures and improve operational efficiency. Contact us to get started.

Download Brochure

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Tank Refurbishment Project Saves Client Over $100,000

Summary This large refining customer is a crude oil refinery located in North America. Acuren has been the primary NDT, inspection and materials engineering service provider to them since 2010,...

Learn More →Acuren Tank Solution Saves Client 60 Outage Days and Over $500,000

Summary This client is a multidisciplinary professional services firm that provides airport fuel consortium administration, fuel infrastructure project and construction management for aviation fuel and ground fuel facilities at major...

Learn More →