STRAP – Steam Turbine Risk Assessment Program

STRAP - Steam Turbine Risk Assessment Program: Extend Time Between Outages, Improve Equipment Availability, Reduce Overall Risk, Reduce Financial Risk.

STRAP – Steam Turbine Risk Assessment Program

- Evaluate Design Adequacy of New Equipment

- Evaluate Fitness-for-Service of Existing Equipment

- Supplement Failure Analysis to Determine Root Causes and Engineer Optimum Repair Solutions

- Provide Quick, Practical, Cost-Effective Solutions

- Design and construction

- Operation

- Maintenance

- Monitoring

- Condition at past outages

- Steam Chemistry

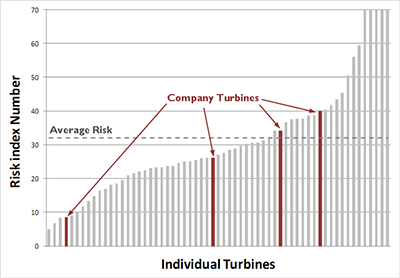

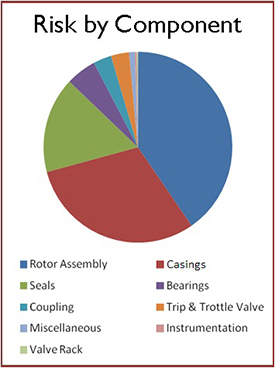

STRAP is the culmination of this synergy of experience and data. The program consists of algorithms that calculate risk (risk = probability of failure x consequence) for the steam turbine generator from the probabilities of failures, failure consequences, and engineering modifying factors included in the programs. These factors are applied to data acquired from questions that are answered for the specific turbine or generator. These questions include information regarding operations and maintenance, construction and design, monitoring, steam chemistry, upgrades and spares, etc. STRAP then calculates the risk of that specific unit.

STRAP was developed based on ASME’s Risk Based Inspection Guideline methodologies. STRAP has been the subject of technical papers and presentations at numerous conferences (ASME, API, EPRI, NUSIS, PowerGen, SAE, TAPPI, and Turbomachinery), three different insurance companies, and one OEM.

Analyses have been completed for over 350 steam turbines and 150 generators. These results reflect 21 turbine OEM’s and 12 generator OEM’s. The units ranged in size from 1300 HP to 890 MW with operating hours ranging from 8,000 to 340,000, and new to 62 years of operation. The turbines had 780 historical failures (failure is an event that caused lost production).

A STRAP evaluation can provide:

STRAP is the culmination of this synergy of experience and data. The program consists of algorithms that calculate risk (risk = probability of failure x consequence) for the steam turbine generator from the probabilities of failures, failure consequences, and engineering modifying factors included in the programs. These factors are applied to data acquired from questions that are answered for the specific turbine or generator. These questions include information regarding operations and maintenance, construction and design, monitoring, steam chemistry, upgrades and spares, etc. STRAP then calculates the risk of that specific unit.

STRAP was developed based on ASME’s Risk Based Inspection Guideline methodologies. STRAP has been the subject of technical papers and presentations at numerous conferences (ASME, API, EPRI, NUSIS, PowerGen, SAE, TAPPI, and Turbomachinery), three different insurance companies, and one OEM.

Analyses have been completed for over 350 steam turbines and 150 generators. These results reflect 21 turbine OEM’s and 12 generator OEM’s. The units ranged in size from 1300 HP to 890 MW with operating hours ranging from 8,000 to 340,000, and new to 62 years of operation. The turbines had 780 historical failures (failure is an event that caused lost production).

A STRAP evaluation can provide:

- Risk mitigation recommendations

- Risk Ranking and Benchmarking of equipment against industry and other company equipment

- Risk contribution ranked by equipment sub-components

- Risk ranked by failure modes

- Risk ranked by operating modes

- Risk ranked by extended operation beyond past overhaul intervals

| RELATED SERVICES | ||||

|---|---|---|---|---|

| Power Generation

Laboratory Services – Materials Testing

NDT & NDE

High Energy Piping Programs & Solutions

QUICK LINKS

QUICK LINKS

|

||||

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →