HRSG Condition Assessment

Gas and Water-Side Inspections. NDE and Metallurgical Analysis. Water/Steam Chemistry Review. Failure Investigations. Don't Delay - HRSG Condition Assessment.

HRSG Condition Assessment

- Gas-Side and Water-Side Inspections

- Visual Inspections, NDE and Metallurgical Analysis

- Water/Steam Chemistry Review and Troubleshooting

- Failure Investigations

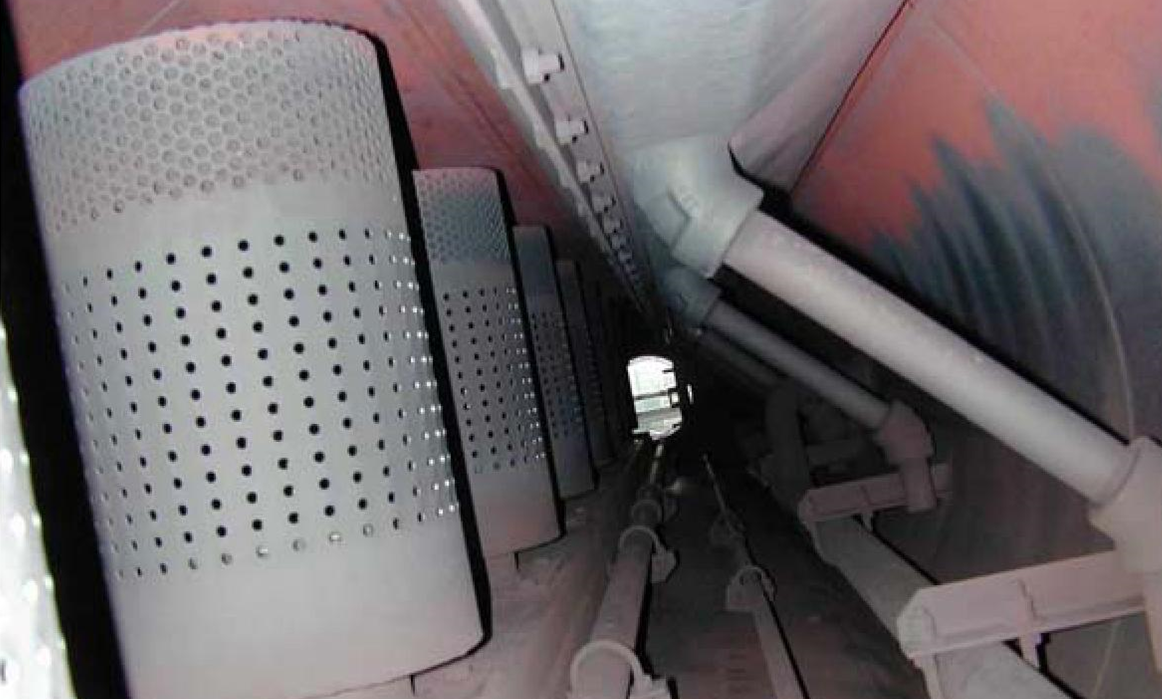

- We examine the gas side of the tubes headers, ductwork, support structure, and duct burners for signs of deterioration from corrosion, cracking, and wear.

- We examine the waterside headers steam drums and risers for corrosion, cracking, FAC, or other damage mechanisms.

- We team with nondestructive testing crews, local or our subcontractors to provide a full condition assessment of your HRSG.

- When problems or failures occur, we provide on-site or in-laboratory metallurgical testing and engineering to get the unit back on line fast.

Water Chemistry is Critical

While HRSGs typically lack the heat flux of a standard fossil-fired unit, they are by no means problem-free when it comes to chemistry-related corrosion. In fact, experience has shown that these units seem to have more tube failures than their fossil-fired counterparts. Common causes include flow accelerated corrosion (FAC), under-deposit corrosion (hydrogen damage, gouging, and pitting), and corrosion fatigue. The complex flow patterns, quick starts and stops, and extended lay-up periods all combine to make proper chemical treatment of HRSGs different than the equivalent pressure fossil-fired boiler.

While HRSGs typically lack the heat flux of a standard fossil-fired unit, they are by no means problem-free when it comes to chemistry-related corrosion. In fact, experience has shown that these units seem to have more tube failures than their fossil-fired counterparts. Common causes include flow accelerated corrosion (FAC), under-deposit corrosion (hydrogen damage, gouging, and pitting), and corrosion fatigue. The complex flow patterns, quick starts and stops, and extended lay-up periods all combine to make proper chemical treatment of HRSGs different than the equivalent pressure fossil-fired boiler.

Don’t Patch It, Fix It

When failures do occur, it is tempting to plug the tube and move on, but understanding the failure mechanism, the “why” is critical to understanding the potential for additional failures. A true root cause analysis of the failure is essential to solve the problem completely.

Acuren has over 40 years of HRSGs, experience in failure analysis in all types of power and industrial boilers, as well as steam and gas turbines. We are experts in the analysis of steam and combustion turbine blade failures. We also understand the process, materials, and operational conditions in combined cycle plants and can work with you to find a way to eliminate failures in the future.

When failures do occur, it is tempting to plug the tube and move on, but understanding the failure mechanism, the “why” is critical to understanding the potential for additional failures. A true root cause analysis of the failure is essential to solve the problem completely.

Acuren has over 40 years of HRSGs, experience in failure analysis in all types of power and industrial boilers, as well as steam and gas turbines. We are experts in the analysis of steam and combustion turbine blade failures. We also understand the process, materials, and operational conditions in combined cycle plants and can work with you to find a way to eliminate failures in the future.

Training

Personnel at many combined cycle plants wear many hats. They operate, maintain, troubleshoot and treat their units. To do it right, they need to know more than just what to do. They need to know the “why to do it”. Acuren can provide on-site training, tuned to your personnel and plant, for a number of areas including water and steam chemistry, nondestructive testing, materials and corrosion issues, and damage repair options.

Personnel at many combined cycle plants wear many hats. They operate, maintain, troubleshoot and treat their units. To do it right, they need to know more than just what to do. They need to know the “why to do it”. Acuren can provide on-site training, tuned to your personnel and plant, for a number of areas including water and steam chemistry, nondestructive testing, materials and corrosion issues, and damage repair options.

| RELATED SERVICES | ||||

|---|---|---|---|---|

| Power Generation

Laboratory Services – Materials Testing

NDT & NDE

High Energy Piping Programs & Solutions

QUICK LINKS

QUICK LINKS

|

||||

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Engineering

Acuren’s world-class teams of over 100 engineers have extensive experience both in the field and in our laboratories to provide a higher level of reliability.

Learn More →Inspection

Acuren offers you an unrivaled spectrum of traditional and advanced nondestructive testing and NDE methods to ensure cost-effective and accurate inspection results.

Learn More →Rope Access

As a pioneer in rope access, Acuren has been working to save time and money on projects in difficult to reach and limited access areas for the past 20 years.

Learn More →Success Stories

Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →