![]()

There are two 30 inch diameter ¼” wall thickness steel water mains, which run along the underside of the bridge over a river way, that provide major water distribution to the community. The mains were installed in 1961 and suffered leakage at support guide attachments due to external corrosion.

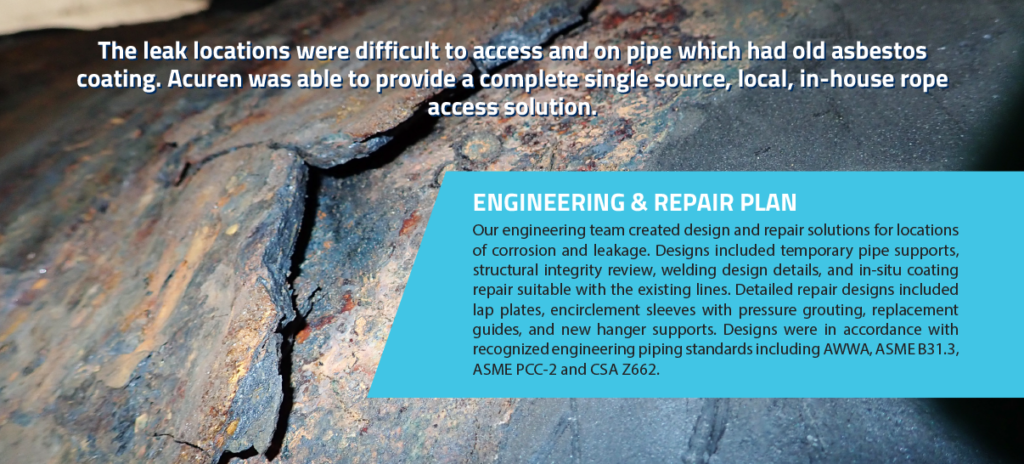

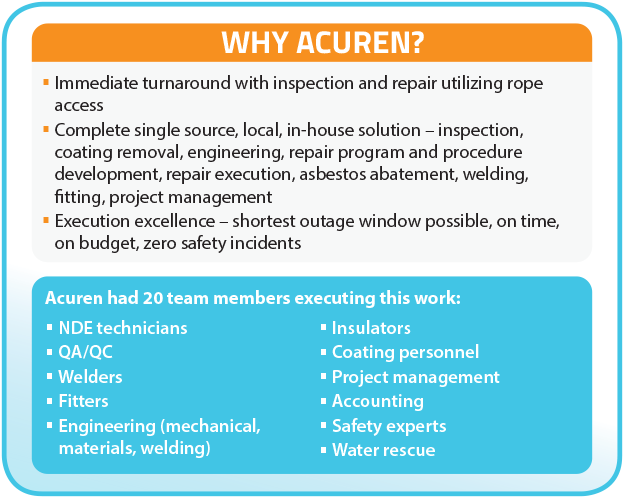

The leak locations were difficult to access and on pipe which had an old asbestos coating. Acuren’s engineering and rope access crew provided a safe, economical, and timely repair solution to get the lines back into operating condition.

The crew performed rope access visual inspection and ultrasonic thickness testing of all 17 guides on each line. With consideration to timing and budget, along with the need to get the lines back into service, the determination was made to repair all guides on one line and the most severely corroded guides on the other line. The pipe had corroded nearly through wall at many of the guides on each line. Acuren completed safe asbestos abatement and removal at locations on the lines requiring further assessment and inspection.

Acuren also performed inspection and assessment of exposed bell and spigot pipe joints and support hangers situated below the bridge expansion joint, which had severely corroded due to overhead water, debris, and road salts. We located and identified through wall corrosion at these locations that were moments away from leakage.

ACUREN IS A SINGLE-SOURCE SOLUTIONS PROVIDER

We were able to complete this work at an estimated 50% cost and time savings when compared with traditional methods utilizing multiple contractors and scaffolding.

Repair Details

- 14 welded lap plate repairs and guide replacements

- Weld metal build-up of corroded pipe at 4 guides

- 2 full encirclement welded sleeves with pressure grout at corroded bell and spigot joints

- 2 support hanger rebuild/fabrication and replacement

- Weld repair inspection

- Coating repairs at weld locations

- QA/QC

Services

- Inspection methods: VT, UT, MT, PT

- Wall thickness survey

- Engineering repair design

- Coating removal

- Asbestos abatement

- Surface repair preparation

- Developed repair procedures

- Performed weld repair in accordance with engineering design

- Re-inspection

- Re-coating

Contact us today at 1-800-218-7450 to find out how we can efficiently execute complicated scopes of work for your projects. We go places, and do things, others simply can’t.