Advanced Diagnostics

Advanced Diagnostics is our expert-driven solution for uncovering the root causes of machinery failures and performance issues, using specialized testing and multichannel data analysis to deliver lasting reliability improvements.

Unlock Maximum Uptime with Advanced Diagnostics

Advanced Diagnostics is a comprehensive approach used by our Reliability Engineering Team to resolve machinery runnability issues and premature failures. Our experts can diagnose and design the solutions to enhance machine availability. The team consists of engineers and technicians with certifications from the Canadian Machinery Vibration Association and the Vibration Institute.

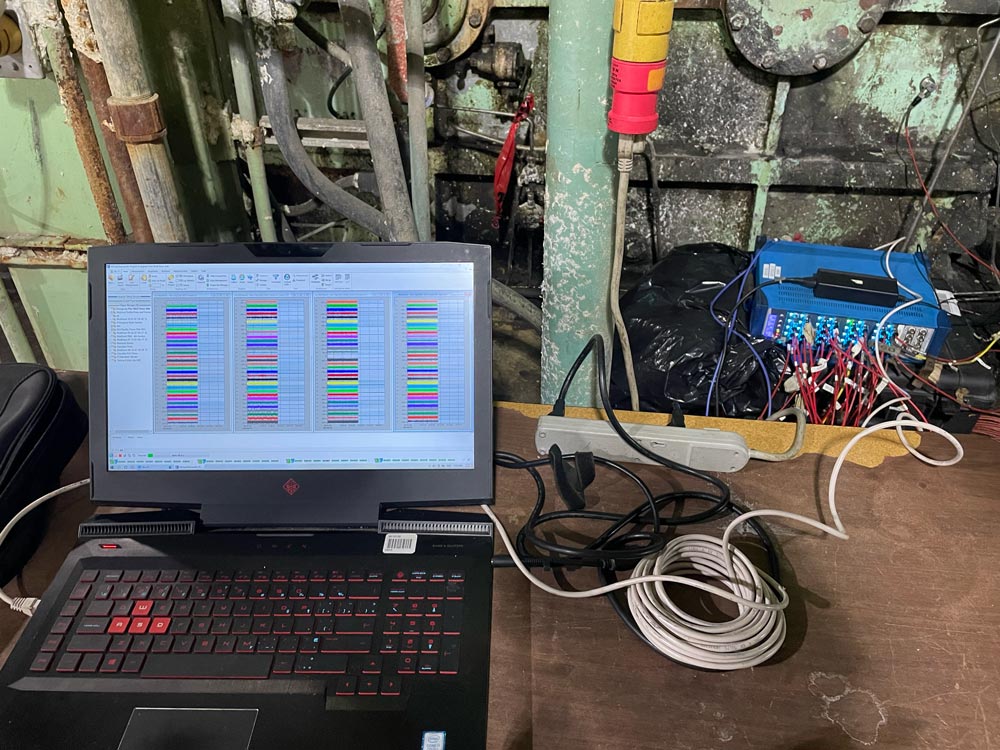

We address requests such as ongoing asset issues where basic vibration analysis has fallen short or increasing a machine's operating speed for higher throughput. Our team performs multichannel data collection, including vibration, pressure, temperature, and operating data simultaneously, enabling complex system modeling and a holistic view of the issue to ensure the root cause is addressed.

Some of the tests and activities that we perform include:

- • Forced Response Frequency (FRF) Testing, to determine resonance issues

- • Transient Data analysis, allowing for diagnoses of intermittent issues

- • Peak Phase and Amplitude

- • Gear and earing analysis

- • Dynamic and static pressure tests

- • Shaft torque, taken dynamically

- • Imbalance checks

- • Strain to develop stress curves on structures and component loading

- • Linear Displacement

- • Impact testing to test for natural frequency of structures as large as a warehouse and as small as a turbine blade

- • Machine speed trials, vibration over time monitored as the machine passes through a speed range to detect critical speeds and resonance issues.

- • Historical Data/Design Review

These tests and others are used in conjunction with advanced analysis techniques and software.

- Modal Analysis – Impact testing can be used in conjunction with machine speed trials to determine areas of resonance. Analysis of this data can also provide insight into methods to either stiffen or dampen the system to reduce vibration amplitudes.

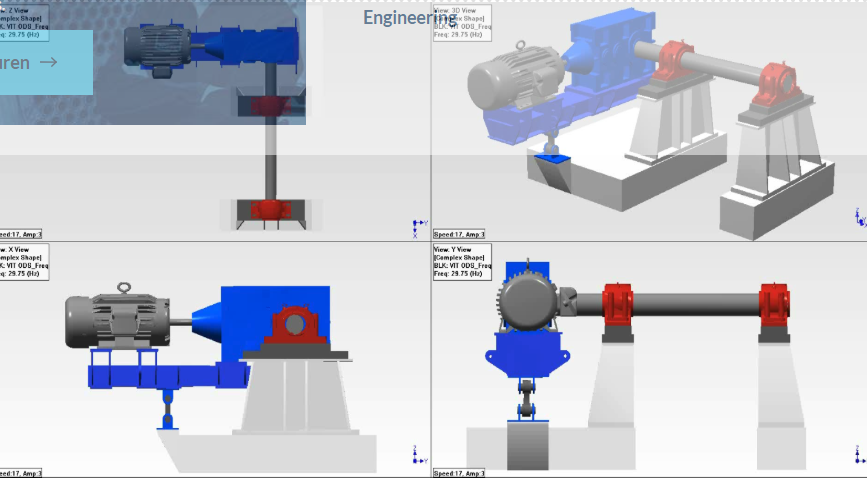

- Operating Deflection Shape Analysis – Data acquired during normal operation can be applied to a computer model to provide a visual representation of how a machine is vibrating.

- Finite Element Analysis and Structural Designs – Our rotating and structural engineering teams work together to design bracing or mass to systems to shift natural frequencies.

Partner With an Industry Leader Today

Our experienced service providers are ready to deliver innovative, reliable solutions tailored to enhance your efficiency, reduce risks, and optimize costs.

Contact Acuren

Additional Services

Condition Based Monitoring

Acuren’s team of reliability engineers and technicians are specialists in the condition based monitoring and maintenance field with decades of experience.

Learn More →Vibration Analysis

Machinery faults such as unbalance, misalignment, bent shafts, mechanical looseness, faults in gear drives, defects in bearings and resonance can be detected by Acuren technicians and engineers using vibration analysis.

Learn More →Finite Element Analysis and Computational Mechanics

Pressure Vessels, Piping, Tanks, Turbines, Industrial Equipment. FEA - A Cost-effective, Accurate Method for Evaluating Equipment and Process Interaction.

Learn More →Success Stories

Reliability Engineering Services Delivers Cost Savings

Summary Richardson Oilseed is one of Canada’s oldest and largest fully-integrated crushing, refining, processing and packaging operations. In the absence of timely manufacturer support for a critical equipment issue, the...

Learn More →Flare Stack - Extending Operating Life of Critical Legacy Asset

Integration across Acuren service lines achieves cost-effective and timely asset life extension This oil and gas customer had a 60-year-old flare stack with cracking and corrosion that was approaching its...

Learn More →Solution Brief - Acuren Partners with An Energy Leader to Provide Access Solutions

Problem Acuren has partnered with an energy company to support their TA/Maintenance program in Fort McMurray, Canada Launched in the fall 2016, an access planner works with planning and execution...

Learn More →