The term asset management is used widely, often in different contexts, but what is it?

Asset management is the coordinated effort to realize value from assets.

The keyword is coordinated. It requires alignment across the organization—operations, maintenance, finance, environmental, human resources, and beyond—so that decisions about assets are made with a common purpose. While the concept sounds simple, in practice it can be challenging. Aligning diverse groups, each with its own priorities, takes structure, discipline, and cultural commitment.

Assets may be physical—like equipment, pipelines, or infrastructure—or intangible, such as data, intellectual property, or workforce capability. In the industrial world, the focus is often on physical assets, but successful asset management takes a broader view. For example, without proper environmental controls, a business may face fines, and poor human–machine interaction can degrade reliability. Both scenarios affect asset performance and, ultimately, business outcomes.

The goal of asset management standards and practices is to break down silos and encourage collaboration, ensuring that every function contributes to long-term organizational success.

A Brief History of Asset Management

Asset management isn’t new. In fact, humans have been managing tools, infrastructure, and resources for centuries. What’s new is our understanding that managing these elements in silos isn’t effective in today’s complex operating environments. Asset management is a term coined to join those silos together and provide alignment towards the overarching company strategy.

The modern concept of asset management began taking shape with PAS 55, a British standard developed in the early 2000s that focused on the optimized management of physical assets. It quickly gained traction across industries such as utilities, transport, and manufacturing.

Eventually, PAS 55 evolved into the ISO 55000 series, a set of international standards that brought global alignment to asset management principles and practices:

- ISO 55000: Overview, principles, and terminology

- ISO 55001: Requirements for an asset management system

- ISO 55002: Implementation guidance

These frameworks help companies bridge the gap between operational needs and business goals, promoting sustainability, resilience, and regulatory compliance.

Asset Management Culture

Asset management is more than maintaining a spreadsheet of equipment. As previously stated it is the coordinated activity of realizing value from assets in a way that aligns with organizational strategy. This involves balancing cost, risk, and performance across an asset’s entire life cycle—from acquisition and operation to maintenance, renewal, or disposal.

It’s also a cultural shift. Companies that truly operate under asset management principles do so across departments—from maintenance and engineering to finance and operations. It’s not just about how assets are managed, but how decisions are made in the organization.

To build a robust asset management culture, organizations should adopt the following foundational principles:

- Value Realization: Assets must contribute to business goals and deliver measurable value.

- Whole-Life Costing: Decisions must consider the full life cycle of the asset, from design to decommission.

- Risk Management: Organizations must identify, assess, and mitigate risks to ensure performance and compliance.

- Strategic Alignment: Asset-related decisions should be connected to the broader business strategy.

It’s not just about the assets themselves; it’s about managing everything that affects them: human resources, data systems, regulations, and even stakeholder expectations.

Asset management goes beyond ownership of the asset to also include needs assessment, strategic planning, and front-end engineering. It includes all adjacent activities required to manage the lifecycle, such as data systems, human resources, environmental, demand, market, and stakeholder input. The company that has a culture of asset management considers the value it derives from its assets when making all decisions about its business.

What Does This Look Like in Practice?

Asset management isn’t a department—it’s a mindset that should permeate the entire organization. Here are the key components in action:

- Asset Identification & Classification: Know what assets you have and their importance to operations.

- Lifecycle Planning: Build maintenance and renewal plans to ensure assets remain productive across their lifespan.

- Risk Management & Compliance: Evaluate threats—regulatory, environmental, physical, or digital—and plan accordingly.

- Performance Optimization: Use data and inspections to optimize reliability and efficiency.

- Investment Planning: Make smarter capital decisions by basing investments on risk and performance data.

Why Asset Management Matters

Asset management is about increasing value not cost-cutting. Organizations that embrace asset management make better decisions, gain clarity over where to invest, and operate more sustainably. The outcome is improved business performance, safety, reliability, and optimized equipment performance. The asset management culture provides a clearer line of sight to organizational goals for all levels and departments.

How Acuren Supports Asset Management

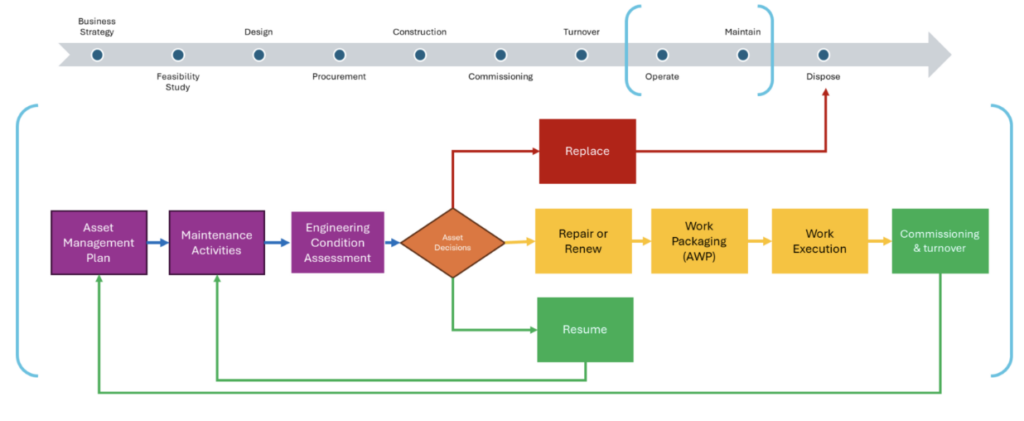

At Acuren, our work is centered on the cycle between operating and maintaining the asset lifecycle, where decisions about asset operations directly influence safety, reliability, and cost. Our teams support this phase by combining engineering assessments with inspections to give operators the information they need to make sound, risk-based choices.

Stretching the asset lifecycle into a linear model better depicts the cycle between operate and maintain. The decision whether to Replace, Repair/Renew, or Resume the operation of an asset is critical to the performance of the business.

In practice, Acuren supports this decision through engineering assessments and inspections of all types. We specialize in understanding how equipment should be evaluated and accurate condition assessments, which leads to better decisions, often leading to cost savings. As an example, we can use fitness for service assessments to resume operations on questionable conditions, or repair eqiupment thought ready for replacement. Additionally, Acuren Engineering develops equipment repair packages, rope access technicians specialize in performing difficult-to-repair and renewal projects, and our inspectors perform commissioning and testing to ensure the asset is ready to be put back into service safely.

What matters is not just fixing a piece of equipment—it’s making sure the decision aligns with broader business goals. By focusing on risk, performance, and lifecycle cost, we help organizations strengthen their asset management culture and maximize value from the resources they already have.

If you’re ready to improve your asset management strategy, contact us today!