Rope access and scaffolding are two different methods used for working at heights in various industries like construction, maintenance and inspection. Rope access involves trained technicians using ropes and harnesses to reach high or hard-to-access areas, while scaffolding involves a temporary structure made of metal or wood to support workers and materials.

Scaffolding is a common sight around construction areas, but the cost of scaffolding adds to overall project fees — and these solutions may not be the best choice for your business in the first place. Is rope access or scaffolding better for you?

Difference Between Rope Access vs. Scaffolding

Scaffolding is often the go-to choice for large-scale projects where extensive access is needed. It is suitable for tasks that require a stable platform, such as painting, bricklaying and structural repairs. Building these platforms involves erecting frameworks from the ground up around buildings or structures. Workers then access elevated areas by climbing or walking on the scaffold. The setup process requires careful planning to ensure stability and safety.

Scaffolding is bulky and visually intrusive, often dominating the exterior of a building during construction or maintenance. It can obstruct entrances and pathways, potentially leading to negative perceptions from local businesses and residents.

In comparison, rope access is a specialized technique where workers use ropes, harnesses and other equipment to access high or hard-to-reach areas. This method often involves abseiling, where workers descend or ascend from the top of a structure. It involves a two-line system for safety — technicians are secured with a primary rope and a backup line.

Commonly used in the aerospace, construction, and oil and gas industries, rope access is ideal for tasks like facade inspections, maintenance of large structures and work on high-rise buildings. It is particularly useful in situations where cranes are impractical or where access is limited. Another advantage of rope access is its minimal visual impact. There is less disruption to the building’s facade and surrounding areas.

Benefits of Rope Access Over Scaffolding

Like any approach, rope access and scaffolding both have their advantages and drawbacks. However, when it comes to specific factors, rope access is the better access method in most cases.

1. Speed

Scaffolding requires a significant amount of time to assemble and disassemble. This lengthy process can lead to extended project timelines and increased labor costs, particularly for shorter-term tasks.

Rope access is the preferred choice for many projects with tight timelines or emergency repairs. Contrary to scaffolding, rope access systems can be set up quickly, allowing technicians to begin work almost immediately. Similarly, dismantling rope access systems is a swift process that allows for a quick return to normal operations once the job is completed.

Because rope access uses ascenders and descenders, workers can work at a faster rate as they move swiftly between different heights.

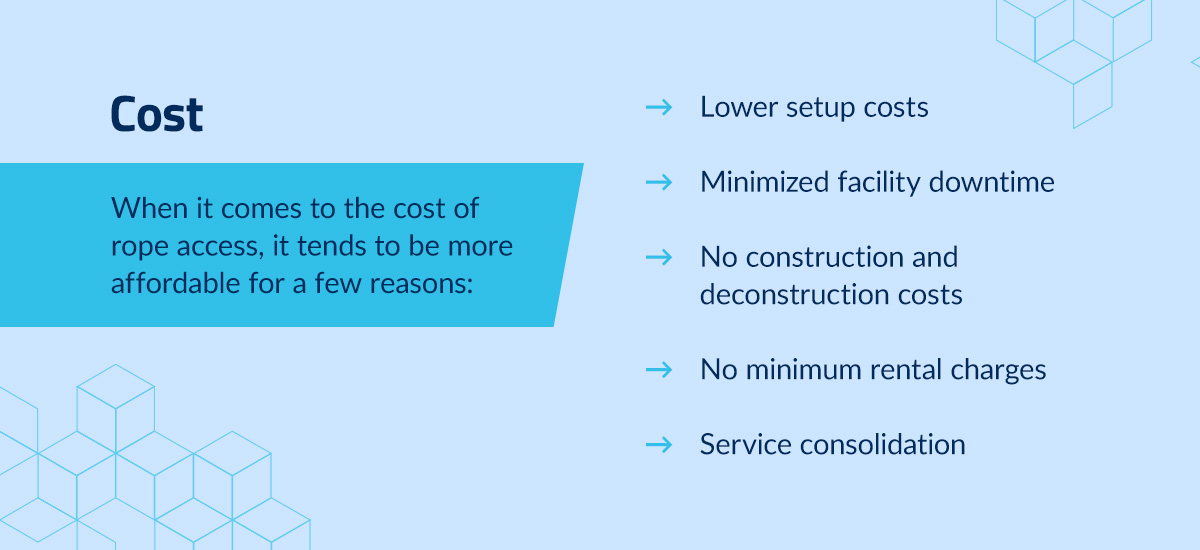

2. Cost

When it comes to the cost of rope access, it tends to be more affordable for a few reasons:

- Lower setup costs: Setting up rope access requires less equipment and fewer workers compared to scaffolding.

- Minimized facility downtime: The speed of rope access setup means projects can be completed faster, which reduces downtime and allows facilities to remain operational. The quicker the work is completed, the less revenue is lost.

- No construction and deconstruction costs: Unlike scaffolding, rope access avoids costs for construction, deconstruction and transportation of large equipment. There are also no extensive setups or takedowns.

- No minimum rental charges: Scaffolding often comes with minimum rental charges, which can add to the overall cost. Rope access does not have these minimums, making it a more cost-effective option for short-duration tasks.

- Service consolidation: Rope access technicians are often trade-qualified to perform the work needed for your project. This consolidation of services eliminates the need for separate contractors.

On average, projects using rope access save between 30% to 70% of their budget compared to those using scaffolding.

3. Safety

Rope access safety regulations are set by international bodies such as the Industrial Rope Access Trade Association (IRATA). Many rope access companies also employ technicians who are certified by the Society of Professional Rope Access Technicians (SPRAT), ensuring they meet rigorous safety standards and are equipped to perform work safely and efficiently.

Contrary to common perceptions, rope access is safer than scaffolding, with significantly lower accident rates. Rope access technicians undergo extensive training that exceeds the requirements for scaffold workers. This training includes safety routines, equipment handling and emergency procedures.

Safety systems within rope access include:

- A two-rope system: The two-rope system secures technicians to a mainline and a backup line. The backup line acts as a fail-safe in case the mainline fails.

- Tethered tools: Technicians use tethered tools and equipment that prevent them from falling and potentially injuring bystanders. This practice enhances the safety of both workers and the public by reducing the risk of accidents associated with dropped tools.

4. Flexibility

Many buildings have architectural features that make access challenging, such as ledges, domed roofs and intricate designs. Technicians can traverse building facades, reach high-rise locations and access confined spaces that scaffolding cannot easily accommodate.

The rigging used for rope access takes up very little space, allowing technicians to work in areas where scaffolding would be impractical. This flexibility is particularly beneficial for projects in urban environments or offshore structures where ground space is limited.

5. Sustainability

Rope access offers more environmental advantages than scaffolding. The reduced need for heavy machinery and extensive setups associated with scaffolding leads to lower noise levels on construction sites for both workers and nearby residents.

Rope access generates less material waste compared to scaffolding. The production of scaffolding materials like steel, aluminum and wood has an environmental impact due to the energy and resources required for their extraction and processing. While steel and aluminum are recyclable, the overall impact of their production and disposal is still significant. Rope access, with its minimal material requirements, reduces the need for new materials and the associated environmental costs of production.

Explore Rope Access Solutions From Acuren

Rope access is faster and more flexible than scaffolding, making it a preferred choice for many businesses needing efficient and safe access to high places. Rope access services provide a specialized solution that’s more cost-effective and sustainable than traditional scaffolding practices. They are a versatile option for businesses with diverse needs.

Acuren is a global leader in rope access solutions. We aim to enhance productivity, reduce risks and optimize costs for our clients by delivering reliable and high-quality industrial services. Our cross-functional integrated industrial service teams are IRATA-certified and work with advanced technologies for any inspection challenge.

For more information about our rope access services, get in touch with our team today.