Home › Archives for Brian J. Cooper, PE, PMP › Page 2

This blog covers some success factors for construction, repair, and maintenance in winter.

With a long history of natural gas infrastructure engineering and recent experience with RNG projects, Acuren’s Integrity and Design team is interested in contributing its expertise in RNG analysis, control, measurement, and transportation to the development of the RNG industry and specific projects.

Faced with anomaly-related pressure reductions and ambiguous ILI results, a client turned to Acuren's engineering team for a comprehensive integrity solution. Acuren managed nitrogen purging, anomaly cutouts, spike and hydrotesting, and pipeline restoration, securing a five-year reassessment interval and re-establishing MOP. Through strategic planning and contingencies, the project exceeded expectations, finishing early and under budget.

In the pipeline sector, 3D modeling is key to more accurate replacements and upgrades of equipment, resulting in less need to force pipe to fit, less need for field welds, and a faster return to service. And that’s good news for pipeline operators, engineers, and regulators alike.

Acuren’s Integrity and Design team can help pipeline operators meet their EFRD evaluation obligations

With increasing demand for natural gas and the success of shale play hydraulic fracturing in the last decade and a half, production in some areas of the United States has surged. Gathering lines have followed suit, with dramatic growth in both mileage and pipe diameters.

Engineering, planning, monitoring, and troubleshooting the nitrogen displacement of a 525-mile pipeline.

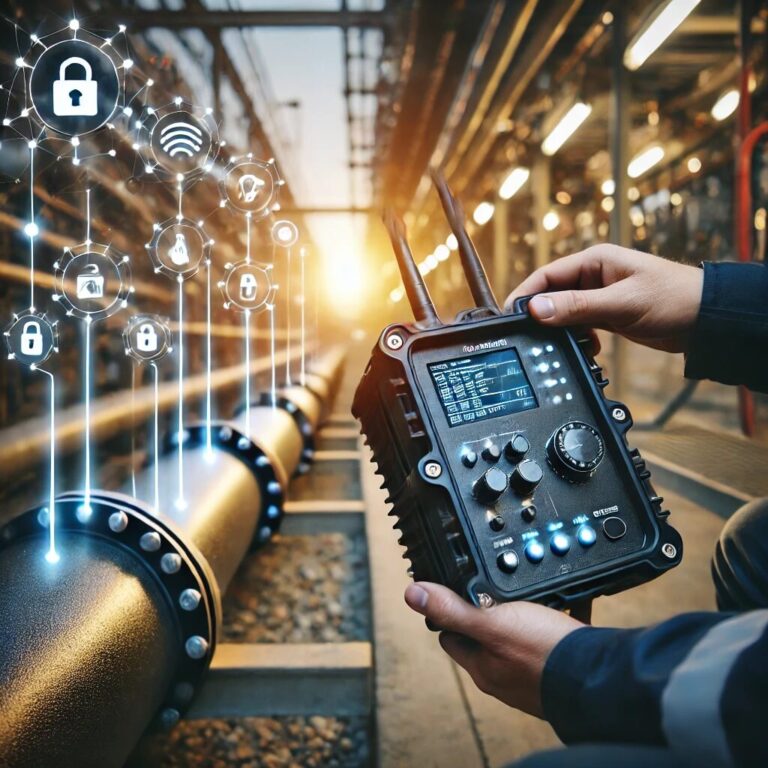

Enhancing the cybersecurity of a pipeline system by installing and configuring a communications gateway that mitigates the risk of security breaches from hackers to a communications interface between a pipeline operator and their customer’s terminal.

Since 2007, Acuren’s Integrity and Design Team has supported West Bay Exploration Company with regulatory compliance for its petroleum pipelines, ensuring documentation is accurate, up-to-date, and audit-ready. By streamlining processes and conducting internal audits, Acuren has minimized regulatory risks and improved audit outcomes. This partnership allows West Bay to focus on safe operations while maintaining its commitment to environmental responsibility.

Over nearly two decades, Acuren’s Integrity and Design Team has worked with a Midwest pipeline operator to strengthen the integrity of 700 miles of natural gas and hazardous liquid pipelines. From assessments to repairs and documentation, the team has improved safety, compliance, and operational efficiency. This collaboration has minimized risks and helped safeguard both communities and the environment.