Project Impact

- Increased threat resistance

- Reduced risk of pipeline failure

- Achieved increased ongoing regulatory compliance

- Enhanced documentation quality and organization

- Improved audit process

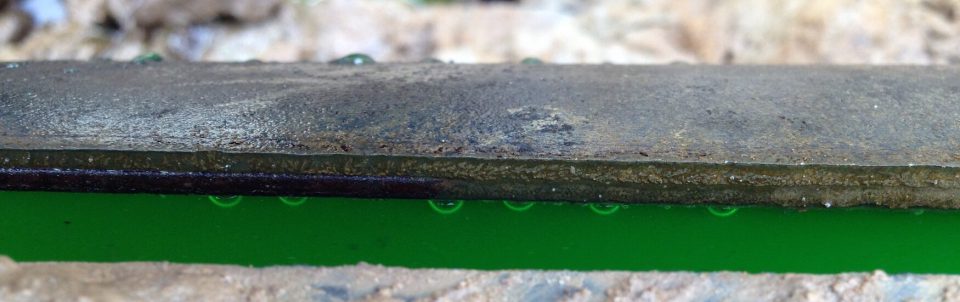

In 2015, in response to a regulatory environment of increased scrutiny, the company asked Acuren to begin overseeing the documentation of all integrity dig, inspection, and repair work and to ensure compliance with PHMSA requirements. The Acuren team works shoulder-to-shoulder with responsible parties at the organization to steward the funding, planning, scheduling, and coordination of the digs. Our experts provide quality assurance for all field records, working closely with the crews to provide training and reinforce the notion that “if it’s not documented, it didn’t happen.” Acuren collaborated with the company to create a cloud database for housing repair plan and dig records along with tools that make information easy to find and communicate. The solutions work well for both field and office team members and have made a significant difference during recent PHMSA audits.

“The work that you all have done to improve our documentation organization and the major improvements to the repair reconciliation process is best in class. We have never been so organized. I appreciate all your efforts. It truly makes my job easier when I have a team who is so good at what they do.”

Integrity Management Team Supervisor Tweet

Integrity management is critical work. Yet, its ever-increasing scope and complexity can strain the bandwidth of operators and cause important details to slip through the cracks, resulting in costly fines, or worse, catastrophic leaks or failures. By bringing Acuren on board to provide the expertise and long-term commitment its integrity management team needed to succeed, the operator has significantly increased the resistance of its pipeline system to threats and reduced the risk of failures. The team has consistently met regulatory compliance standards and streamlined the audit process. Most importantly, the liquid petroleum transportation services company is doing its part to protect the environment, the public, and its own business and to ensure an even safer future for everyone.